Super lightweight, fabric-based solar cell turns any surface into a power generator

This innovation is so thin, it can turn just about any surface into a power generator, paving the way for a host of new applications.

[Oct. 30, 2023: Staff Writer, The Brighter Side of News]

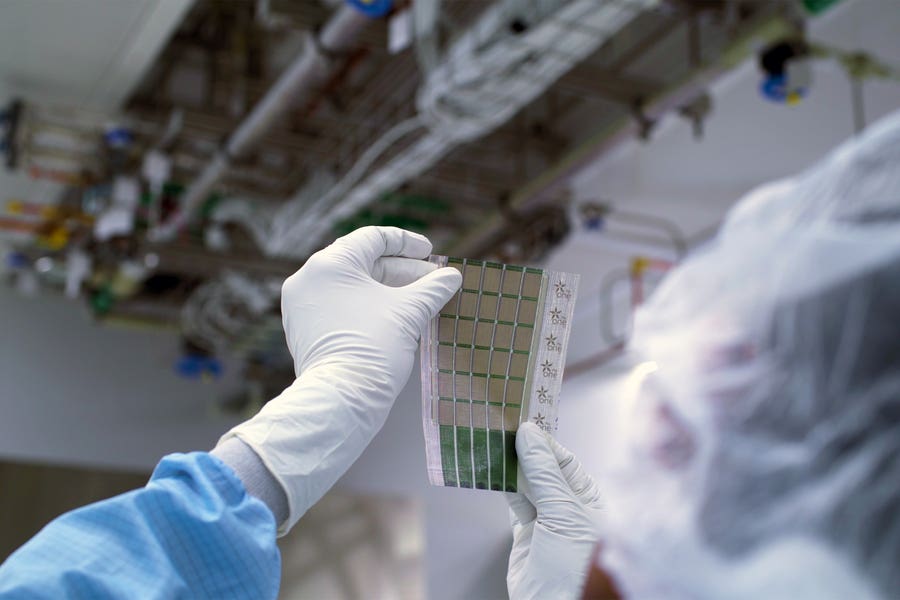

MIT researchers have developed a scalable fabrication technique to produce ultrathin, lightweight solar cells that can be stuck onto any surface. (CREDIT: Melanie Gonick, MIT)

Researchers at the Massachusetts Institute of Technology (MIT) have taken a revolutionary step forward in renewable energy technology. They've developed a super lightweight, fabric-based solar cell. This innovation is so thin, it can turn just about any surface into a power generator, paving the way for a host of new applications.

Traditional solar panels are encased in thick glass and framed in aluminum, making them heavy and somewhat inflexible. However, the MIT team's design is incredibly thin and flexible. They've bonded these solar cells, which are thinner than a human hair, to a durable, lightweight fabric. The result? Solar cells that are just a fraction of conventional solar panels' weight, but generate a staggering 18 times more power per kilogram.

Beyond their power efficiency, these cells can be attached to almost any surface. Imagine sails on a boat that also generate power, or tents used in disaster relief that provide their own energy. Drones could have extended flying ranges by incorporating this lightweight technology onto their wings.

The thin-film solar cells weigh about 100 times less than conventional solar cells while generating about 18 times more power-per-kilogram. (CREDIT: Melanie Gonick, MIT)

Vladimir Bulović, a senior figure at MIT and a driving force behind this project, emphasized the importance of integrability in solar technology. He stated, “The lightweight solar fabrics enable integrability, providing impetus for the current work. We strive to accelerate solar adoption, given the present urgent need to deploy new carbon-free sources of energy.”

The Journey to Solar Fabric

This isn't MIT's first foray into ultra-thin solar cells. Six years ago, their team crafted cells so light they could float on a soap bubble. But scaling up the manufacturing of these cells was challenging due to their complex production methods. The team's goal then shifted to creating entirely printable solar cells using ink-based materials, and they succeeded.

The process involves using nanomaterials in the form of printable electronic inks. In a dedicated clean room, these inks are then applied layer by layer onto a super-thin substrate using a special coating machine. The final touch is added using a screen printing method to deposit an electrode, after which the ultralight solar module can be peeled off the substrate.

Related Stories

However, these freestanding modules were delicate. The team needed a substrate that was lightweight yet sturdy. Their solution? A commercial fabric known as Dyneema. This robust material, which once helped lift a sunken cruise ship, proved to be the ideal companion for the solar cells. By sticking the solar modules onto sheets of Dyneema with a UV-curable adhesive, they developed an ultra-light, yet robust solar structure.

Mayuran Saravanapavanantham, a co-lead author on the project, mentioned, "Our approach decouples the solar cell manufacturing from its final integration.”

Outperforming the Traditional

When tested, the fabric-based solar cells could generate up to 730 watts of power per kilogram on their own, and about 370 watts-per-kilogram when attached to Dyneema fabric. To put that in context, it would only add 44 pounds to a rooftop to produce the same amount of energy as a traditional 8,000-watt solar installation in Massachusetts.

Durability tests were equally impressive. Even after being rolled and unrolled more than 500 times, the solar cells retained over 90% of their original power-generating capabilities.

However, these solar cells still face challenges. The organic materials used in the cells might degrade when exposed to moisture and air. Encasing them in heavy glass, as done with traditional solar cells, would negate their lightweight advantage. Jeremiah Mwaura, another key researcher on the project, highlighted their plans to develop ultrathin protective packaging solutions to circumvent this issue.

The MIT team has achieved the thinnest and lightest complete solar cells ever made, they say. To demonstrate just how thin and lightweight the cells are, the researchers draped a working cell on top of a soap bubble, without popping the bubble. (CREDIT: Joel Jean and Anna Osherov)

Mwaura added, “We are working to remove as much of the non-solar-active material as possible... This would accelerate the translation of this technology to the market.”

MIT's pioneering work is a beacon for the future of solar technology. With the urgent need to reduce carbon footprints and find alternative energy sources, innovations like this ultralight solar fabric are not just impressive—they're essential. As these solar cells edge closer to the market, they could redefine how we harness the sun's energy, making our world cleaner and more sustainable.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.