Stainless ‘Super Steel’ revolutionizes green hydrogen production from seawater

New stainless steel drastically cuts costs for green hydrogen production, offering corrosion resistance and sustainability for industrial use

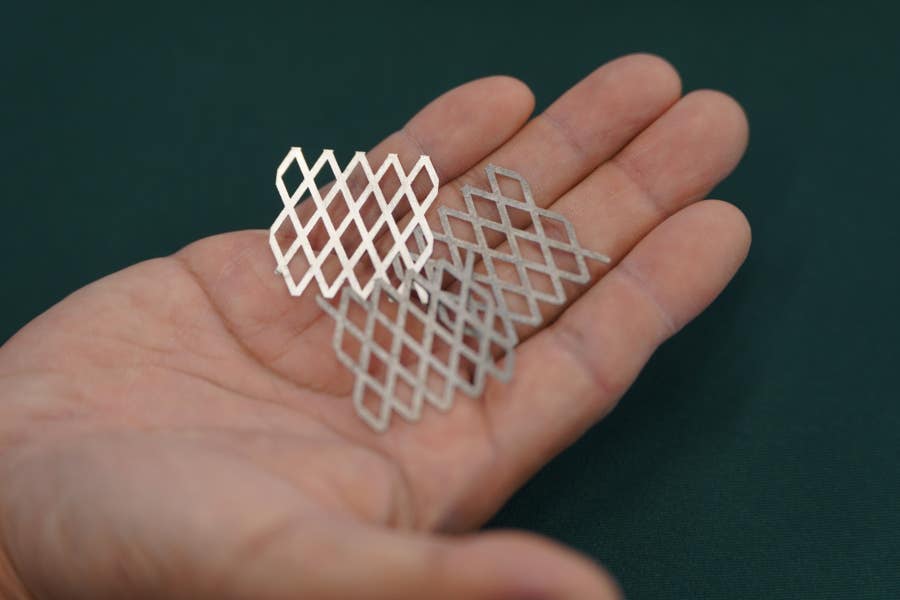

The novel stainless steel for hydrogen developed by the team. (CREDIT: Hong Kong University (HKU))

A new stainless steel technology could transform green hydrogen production and advance the global transition to clean energy.

The innovation, developed at the University of Hong Kong (HKU) under the leadership of Professor Mingxin Huang, represents a major leap in creating cost-effective and corrosion-resistant materials for water electrolysis systems.

Named stainless steel for hydrogen (SS-H2), this breakthrough provides a sustainable and economically viable solution for producing green hydrogen.

Pioneering Green Hydrogen with SS-H2

Green hydrogen, produced by splitting water into hydrogen and oxygen using renewable electricity, holds immense promise for reducing carbon emissions. However, the high cost and material limitations of current electrolysis systems have hindered widespread adoption.

Structural components in these systems, often made from gold- or platinum-coated titanium, contribute significantly to expenses.

SS-H2 addresses this challenge by offering comparable corrosion resistance to titanium at a fraction of the cost. This remarkable material was developed using a "sequential dual-passivation" technique, an innovative process that combines chromium- and manganese-based protective layers.

Dr. Kaiping Yu, the first author of the research, noted, “Initially, we did not believe it because the prevailing view is that manganese impairs the corrosion resistance of stainless steel. Mn-based passivation is a counter-intuitive discovery, which cannot be explained by current knowledge in corrosion science. However, when numerous atomic-level results were presented, we were convinced. Beyond being surprised, we cannot wait to exploit the mechanism."

Related Stories

- Replacing fossil fuels with hydrogen and electricity won’t fully eliminate greenhouse gases, study finds

- Innovative new process makes hydrogen from solar power and agricultural waste

- Emission-free hydrogen generator can power your home for days using less than 2 liters of water

The stainless steel’s corrosion resistance extends even to saltwater environments, opening new possibilities for producing green hydrogen directly from seawater. The material can withstand chloride-rich conditions at ultra-high potentials of up to 1700 millivolts, far exceeding the performance of traditional stainless steel.

Industrial Applications and Cost Implications

The economic impact of SS-H2 is profound. A standard 10-megawatt proton exchange membrane (PEM) electrolysis system, costing approximately HK$17.8 million, could see material expenses cut by up to 40 times with SS-H2. This cost reduction positions the material as a game-changer for industrial hydrogen production.

“From experimental materials to real products, such as meshes and foams, for water electrolyzers, there are still challenging tasks at hand. Currently, we have made a big step toward industrialization. Tons of SS-H2-based wire has been produced in collaboration with a factory from the Mainland. We are moving forward in applying the more economical SS-H2 in hydrogen production from renewable sources,” said Professor Huang.

The material’s dual-passivation layers, particularly the innovative manganese-based layer, provide unprecedented resistance to corrosion. This ensures durability in harsh environments, reducing maintenance costs and enhancing the overall efficiency of hydrogen production systems.

Broadening Horizons: SS-H2 and Green Hydrogen

Beyond its immediate impact on hydrogen production, SS-H2 holds potential for reshaping various industries. The use of green hydrogen, enabled by cost-effective materials like SS-H2, spans several industrial applications, including:

- Ammonia Production: Essential for fertilizers and industrial chemicals, ammonia can be produced using green hydrogen without greenhouse gas emissions.

- Oil Refining: Hydrogen facilitates desulfurization, producing cleaner fuels. Using green hydrogen in this process minimizes carbon footprints.

- Steelmaking: Hydrogen-based direct reduction of iron ore offers a sustainable alternative to traditional methods, significantly lowering emissions.

- Methanol Production: A versatile fuel, methanol derived from green hydrogen supports cleaner transportation and power generation.

Companies such as Shell, Linde, and Bloom Energy are already integrating green hydrogen into their operations. For instance, Shell is pursuing large-scale green hydrogen projects globally, while Linde develops advanced hydrogen technologies across diverse markets.

Overcoming Challenges in Stainless Steel Technology

Stainless steel’s corrosion resistance, long reliant on chromium, has faced limitations in highly oxidative environments. Even advanced stainless steels like 254SMO are prone to transpassive corrosion at high potentials. SS-H2, however, breaks through these barriers with its dual-layer passivation mechanism. The manganese-based layer forms on top of the chromium layer, preventing degradation in environments rich in chloride ions.

This achievement builds on Professor Huang’s history of innovative materials research, including anti-COVID-19 stainless steel in 2021 and ultra-strong Super Steel in earlier years. His team’s dedication highlights the transformative potential of material science in addressing urgent global challenges.

The transition of SS-H2 from laboratory to industry is underway. With tons of material already produced, the focus is shifting toward large-scale applications. As industries adopt this innovative stainless steel, the potential to drive down costs and emissions grows, paving the way for a sustainable energy future.

The development of SS-H2 not only aligns with the global push for decarbonization but also underscores the importance of scientific exploration. By challenging established knowledge and pursuing unconventional ideas, breakthroughs like SS-H2 become possible, propelling humanity toward a cleaner, greener future.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joseph Shavit

Head Science News Writer | Communicating Innovation & Discovery

Based in Los Angeles, Joseph Shavit is an accomplished science journalist, head science news writer and co-founder at The Brighter Side of News, where he translates cutting-edge discoveries into compelling stories for a broad audience. With a strong background spanning science, business, product management, media leadership, and entrepreneurship, Joseph brings a unique perspective to science communication. His expertise allows him to uncover the intersection of technological advancements and market potential, shedding light on how groundbreaking research evolves into transformative products and industries.