Scientists discover a cleaner way to produce ammonia to help with food and energy security

Ammonia is a cornerstone of the global agricultural industry, serving as a key ingredient in fertilizers that have supported food production

Ammonia is a cornerstone of the global agricultural industry, serving as a key ingredient in fertilizers that have supported food production for over a century. Additionally, it plays a crucial role in cleaning products and holds potential as a carbon-free fuel alternative for vehicles.

Traditionally, synthesizing ammonia from molecular nitrogen has been an energy-intensive process due to the high temperatures and pressures required. However, scientists from the Department of Energy's Lawrence Berkeley National Laboratory (Berkeley Lab) have developed a groundbreaking method to produce ammonia at room temperature and pressure.

Since 1909, the Haber-Bosch process has been the industry standard for ammonia synthesis. This process involves reacting molecular nitrogen (N2) with hydrogen gas using metal-based catalysts under extreme conditions.

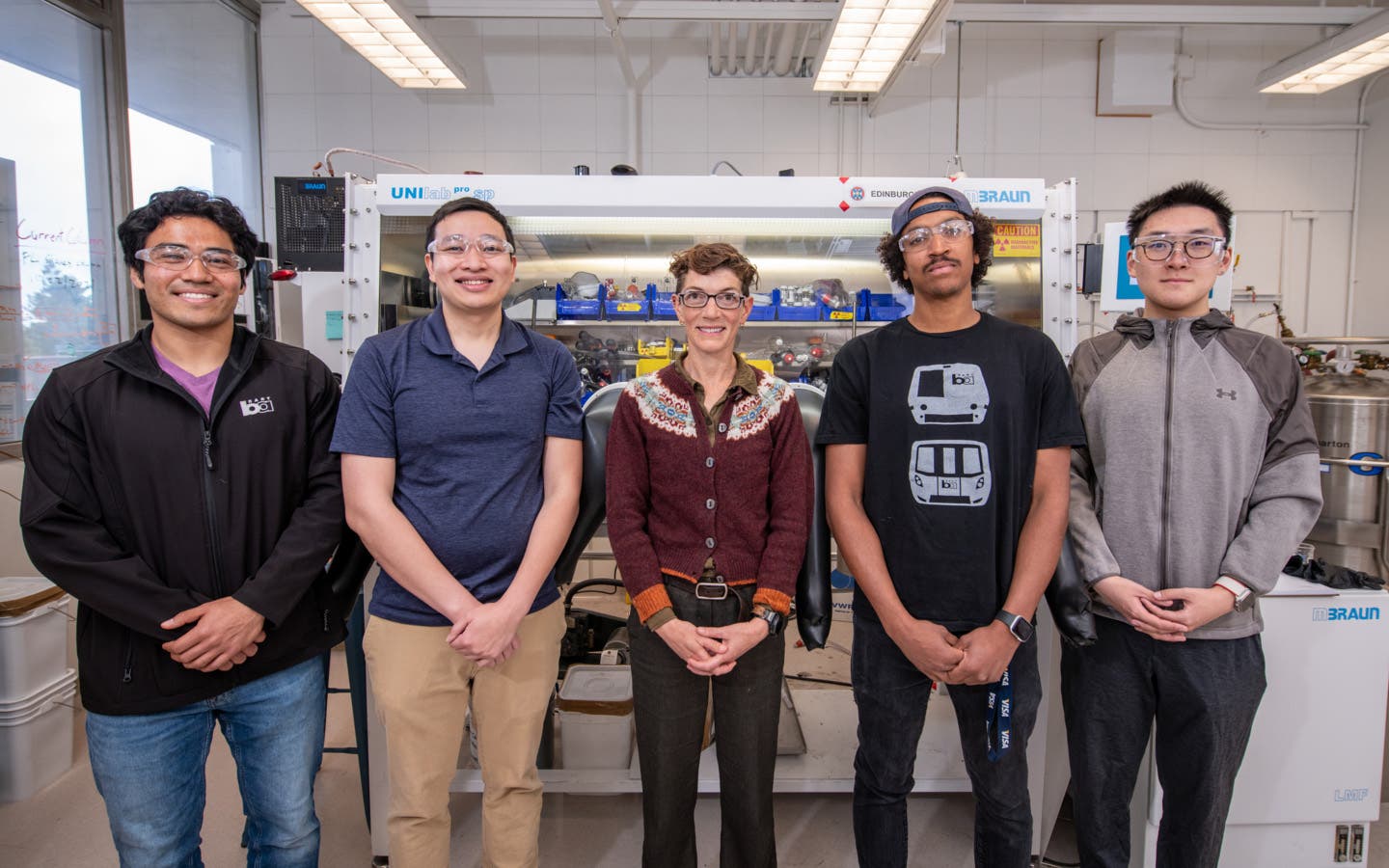

Polly Arnold, a senior staff scientist and the director of the Chemical Sciences Division at Berkeley Lab, has discovered that rare-earth metal catalysts can facilitate this reaction at room temperature, potentially revolutionizing the field.

“Nobody expected rare earth metals to do this reaction. They’ve expanded our arsenal of potential ambient condition catalysts,” says Arnold, who is also a professor of chemistry at UC Berkeley.

Rare-earth metals, despite their name, are relatively abundant and have diverse applications in electronics, lasers, and magnetic materials. “Some rare-earth metals are nearly as common as copper, and their salts are less toxic than metals currently used in catalysis,” explains Anthony Wong, a postdoctoral researcher in Arnold’s group at UC Berkeley and the lead author of the study published in Chem Catalysis.

From a fundamental perspective, rare-earth metals possess additional electrons compared to transition metals, granting them unique opto-magnetic properties.

Related Stories

While chemists have not fully understood the potential of these electrons in reactions, rare-earth metals binding to molecular nitrogen has been known since the 1990s. However, using them to create nitrogen-functionalized chemicals like ammonia or amines from N2 catalytically has remained elusive until now.

Wong, Arnold, and their team designed compounds that connect two rare-earth metals with phenolate linkages, forming a rectangular cavity. Molecular nitrogen diffuses into this cavity, forming bonds with the metals, which activates the gas.

Electrons from a potassium source then attack the activated nitrogen, cleaving its bonds. In its standard forms, nitrogen forms three covalent bonds with hydrogen atoms or other reactants, resulting in symmetrical ammonia or amines.

“Our catalysts activate and hold the dinitrogen, while different reagents come in and react to form various products,” says Arnold. She plans to replace the potassium reagent with electrodes, potentially derived from renewable sources like solar cells, as a source of electrons.

The researchers will next explore how to use rare-earth metals to synthesize additional nitrogen-containing products by adjusting the shape and size of the cavity. “Our next step is to explore and understand which rare-earth metal properties impact the chemistry,” says Wong.

While the new process is not expected to replace the industrial Haber-Bosch process, which produces around 200 million metric tons of ammonia annually, it offers significant benefits. The Haber-Bosch process consumes approximately 2% of the world’s energy and creates geographic inequities in ammonia availability. “That’s not food justice,” states Arnold. Wong adds, “We need better ways of producing ammonia that are less energy-intensive and can be conducted at ambient temperatures and pressures to help with food and energy security.”

Their patented technology has the potential to bring fertilizers and chemically specific nitrogen products to regions without access to pipelines, reducing costs and energy consumption. As the world seeks more sustainable agricultural practices and cleaner energy sources, this innovative approach to ammonia synthesis represents a promising step forward.

Uses for Ammonia

Ammonia (NH₃) is a versatile chemical with numerous applications across various industries. Here are some of the most intensive uses of ammonia in the world:

Fertilizers: Ammonia is a key component in the production of nitrogen-based fertilizers, such as urea, ammonium nitrate, and ammonium sulfate. These fertilizers are essential for modern agriculture to enhance crop yields.

Industrial Refrigeration: Ammonia is widely used as a refrigerant in industrial refrigeration systems due to its high energy efficiency and low environmental impact compared to other refrigerants.

Chemical Manufacturing: Ammonia is used as a building block for the synthesis of various chemicals, including nitric acid, hydrogen cyanide, and other nitrogen-containing compounds.

Water Treatment: Ammonia is used in water treatment processes to help remove impurities and stabilize pH levels, particularly in municipal water systems.

Explosives: Ammonium nitrate, derived from ammonia, is a key ingredient in explosives used for mining, construction, and demolition.

Textile Industry: Ammonia is used in the textile industry for dyeing, bleaching, and treating fabrics. It helps to set dyes and improve fabric quality.

Pharmaceuticals: Ammonia is used in the pharmaceutical industry for the production of various drugs and as a reagent in laboratory processes.

Cleaning Agents: Ammonia is a common ingredient in household and industrial cleaning agents due to its ability to dissolve grease and grime effectively.

Fuel: Ammonia is being explored as a potential alternative fuel source for internal combustion engines and fuel cells, as it can be used to store and transport hydrogen.

Pulp and Paper Industry: Ammonia is used in the pulp and paper industry for pulping wood and as a part of the Kraft process, which involves breaking down the wood into cellulose fibers.

These uses highlight the importance of ammonia in various sectors, contributing significantly to industrial processes, agriculture, and environmental management.

For more green news stories check out our Green Impact section at The Brighter Side of News.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.