Scientists created the world’s thinnest spaghetti

Researchers create eco-friendly nanofibers from flour, promising breakthroughs in wound healing, drug delivery, and sustainable materials.

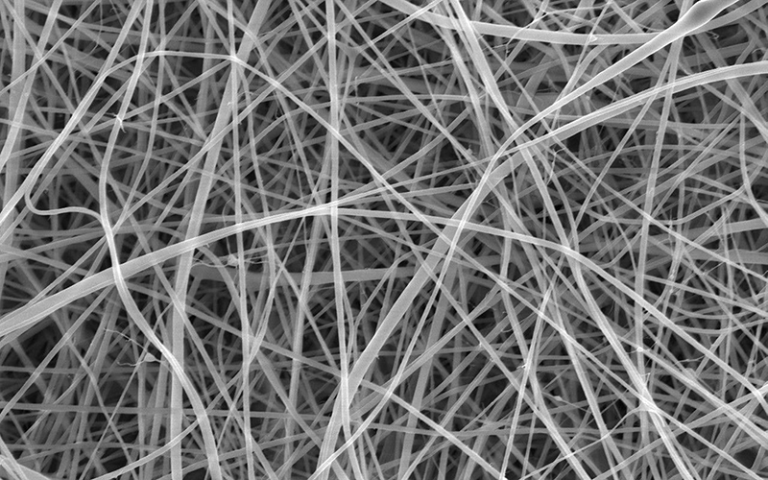

UCL’s 372-nanometer flour-based nanofibers offer a sustainable alternative for wound dressings, tissue scaffolds, and energy applications. (CREDIT: Beatrice Britton / Adam Clancy)

The next wave of nanotechnology is emerging from an unexpected place—the kitchen pantry. A research team at University College London (UCL) has crafted the world’s thinnest spaghetti using wheat flour, with each strand measuring just 372 nanometers across.

This isn’t a culinary experiment but a groundbreaking step toward eco-friendly nanofibers that could revolutionize fields like medicine, energy, and materials science.

The Promise of Starch Nanofibers

Starch, produced by most green plants, is the second most abundant biomass on Earth after cellulose. Its role as a natural polymer makes it an attractive material for nanotechnology.

Starch’s biodegradable and biocompatible nature, coupled with its mechanical flexibility and ability to be chemically modified, positions it as a critical resource for applications ranging from wound dressings to energy storage.

Nanofibers made from starch offer unique properties: their high surface area makes them ideal for biomedical uses, such as drug delivery, tissue scaffolding, and advanced filtration systems.

However, creating starch nanofibers at scale has been limited by the energy-intensive and wasteful process of starch extraction and purification. This method involves steeping plant matter in chemical solutions, washing out impurities, and drying the material.

The process consumes significant energy—160 kilowatt-hours per ton—and 10,000 liters of water per ton, producing contaminated wastewater that requires treatment. The UCL research offers an alternative by sidestepping this purification process altogether.

Related Stories

From Wheat Flour to Nanofibers: A New Approach

The UCL team, led by Dr. Adam Clancy and Professor Gareth Williams, developed a method to create nanofibers directly from white flour, which is a more environmentally friendly and readily available starch-rich material. White flour contains approximately 80% starch, 15% protein, and 5% other components like cellulose and fats.

Unlike purified starch, the proteins and other impurities in flour initially posed challenges for fiber formation due to their impact on viscosity and polymer entanglements. However, the researchers overcame these obstacles by leveraging a process called electrospinning.

Electrospinning is a technique that uses an electric charge to draw threads of material out of a liquid solution. In this case, the researchers dissolved flour in warm formic acid to create a spinning "dope" with the right viscosity and polymer properties.

The formic acid breaks apart the tightly wound helical structures of starch, which are normally too large to serve as nanofiber building blocks. This process unravels the starch's molecular coils and disrupts its crystalline granules, allowing polymer entanglement necessary for spinning.

Once the solution was prepared, it was ejected through a needle charged with electricity. As the solution flew toward a grounded metal plate, the formic acid evaporated, leaving behind a mat of ultrafine starch fibers.

The resulting fibers measured just 372 nanometers in diameter, narrower than many wavelengths of light and far thinner than even the smallest mass-produced pasta, capelli d’angelo (angel hair), which is 800 microns wide.

Nanofibers: Properties and Applications

Nanofibers offer unique advantages over larger fibers due to their incredibly high surface-area-to-volume ratio. This property makes them especially promising for applications like wound dressings, where porosity allows moisture and oxygen to pass through but prevents bacterial intrusion.

Additionally, their nanoscale dimensions mimic the body’s extracellular matrix—a complex network of proteins and molecules that supports cell growth—making them an excellent scaffold for tissue regeneration.

Professor Gareth Williams noted, “Nanofibers made of starch show potential for use in wound dressings as they are very porous. In addition, nanofibers are being explored for use as a scaffold to regrow tissue, as they mimic the extracellular matrix.”

In energy storage, starch nanofibers could be carbonized to form electrodes for supercapacitors, which are critical for advanced energy systems. They could also serve as membranes for nanofiltration, enabling the separation of particles and molecules at a scale unachievable with traditional filters.

Overcoming Challenges with Flour-Based Nanofibers

The transition from purified starch to flour introduces complexities. Flour contains proteins like glutenins and gliadins, as well as cellulose and non-starch polysaccharides. These impurities increase the viscosity of the solution, making fiber formation more challenging. Yet, the impurities are not inherently detrimental to the nanofibers' functionality.

By using formic acid as the solvent, the researchers overcame this hurdle. Formic acid not only dissolves the starch but also modifies its chemical structure temporarily, breaking down the tight helices into smaller, more flexible chains. The warming and subsequent cooling of the solution further enhanced its consistency, ensuring that the fibers could form reliably during electrospinning.

The environmental advantages of using flour instead of purified starch are significant. Flour production requires only 60 kilowatt-hours per ton of energy—less than half the energy needed for starch purification—and does not produce contaminated water. Additionally, flour is widely available and cost-effective, making it a sustainable alternative for nanofiber production.

Dr. Clancy emphasized, “Purifying starch requires lots of processing. We’ve shown that a simpler way to make nanofibers using flour is possible. The next step would be to investigate the properties of this product. We would want to know, for instance, how quickly it disintegrates, how it interacts with cells, and if you could produce it at scale.”

The team’s creation significantly outstrips the finest traditional pasta, su filindeu, or “threads of God,” handmade in Sardinia. These fibers measure around 400 microns—1,000 times thicker than the UCL nanofibers. While the historical craftsmanship is unparalleled, the researchers were quick to point out that their invention serves a completely different purpose.

“This isn’t meant to replace pasta,” Professor Williams joked. “It would overcook in less than a second.”

Next Steps for Nanofiber Technology

The success of flour-based nanofibers opens the door to further research. The team plans to investigate how these fibers interact with cells, their structural stability in biological environments, and the feasibility of large-scale production. Scaling up could involve optimizing the electrospinning process to handle larger volumes and exploring the effects of different flour types on fiber properties.

With their low cost, environmental benefits, and versatility, flour-based nanofibers have the potential to transform industries ranging from healthcare to energy. This innovative approach marks a significant step forward in sustainable materials science, proving that sometimes, the smallest threads can weave the biggest possibilities.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.