Scientists create recyclable alternative to durable plastics

Cornell researchers have developed a recyclable thermoset plastic from bio-based materials, reducing plastic waste and improving sustainability.

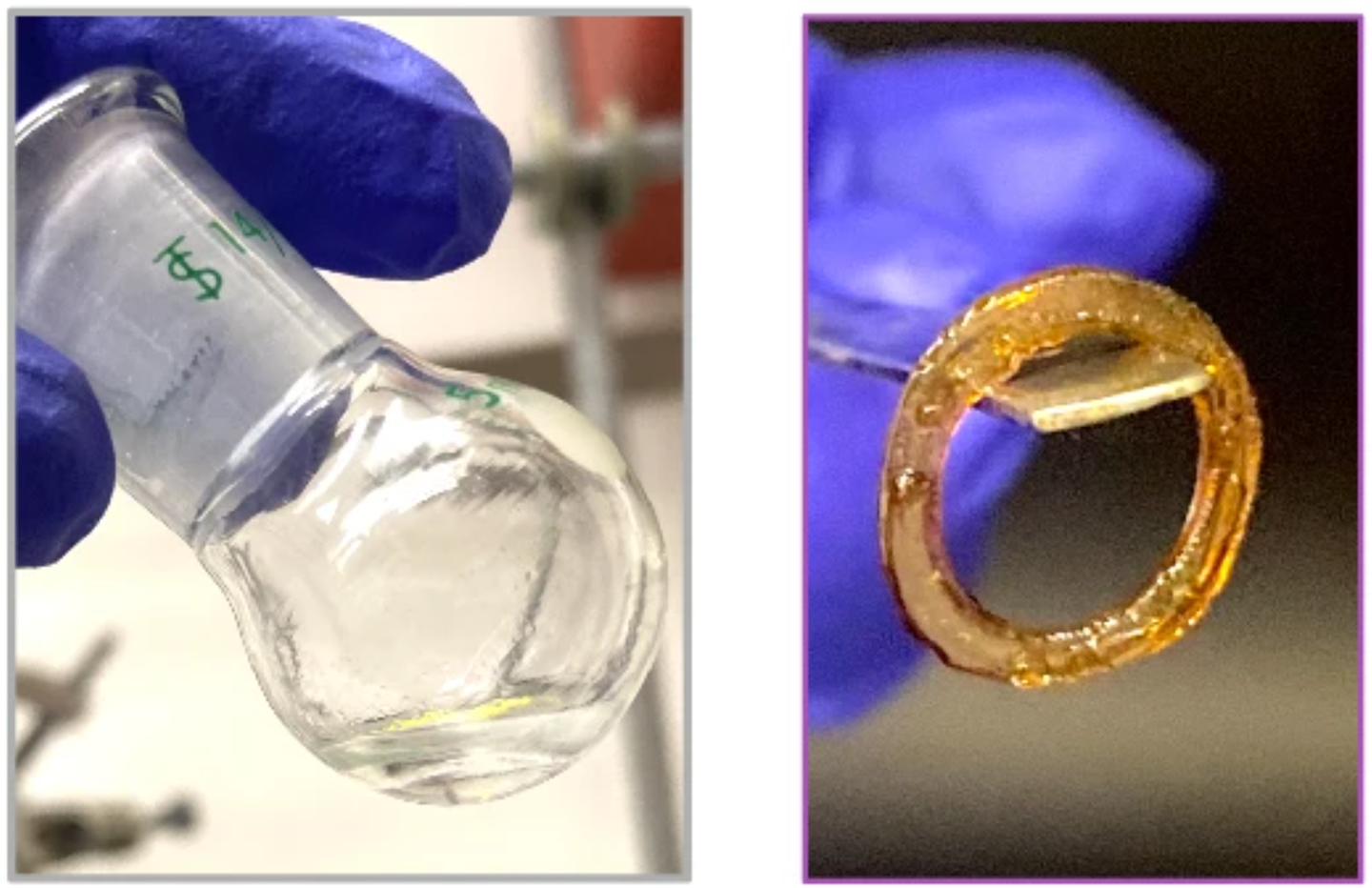

Cornell scientists have created a recyclable thermoset plastic using bio-based monomers. (CREDIT: Nature)

Plastic waste is a growing environmental crisis, with thermosets among the most problematic materials. These durable plastics, used in car tires, replacement hip joints, and aerospace coatings, resist degradation and recycling.

However, researchers at Cornell University have developed a recyclable alternative using a bio-based monomer that could transform the way plastics are made and disposed of.

The Challenge of Recycling Thermosets

Thermosets make up 15-20% of all polymers produced globally, amounting to 60 million tons each year. Their strength comes from a crosslinked polymer structure that ensures durability but prevents breakdown and reuse. Once formed, thermosets cannot be melted and reshaped like traditional plastics, meaning they end up in landfills or are incinerated, releasing harmful emissions.

“Currently, zero percent of the world’s thermoset materials are recycled – they’re either incinerated or thrown in landfills,” said Brett Fors, professor of chemistry and chemical biology at Cornell.

Finding a sustainable solution for these materials has been a long-standing challenge. While some researchers have explored multi-functional monomers capable of forming crosslinked structures, existing methods require high temperatures, chlorinated solvents, or long reaction times. Many of these alternatives remain difficult to recycle or degrade.

A New Approach with Dihydrofuran

The Cornell team has introduced a novel approach using 2,3-dihydrofuran (DHF), a bio-derived, commercially available cyclic vinyl ether. DHF can undergo two different polymerization processes—ring-opening metathesis polymerization (ROMP) and cationic polymerization—to create a crosslinked thermoset.

DHF-based thermosets demonstrate comparable properties to commercial thermosets, including high-density polyurethane and ethylene propylene rubber. However, unlike their petroleum-based counterparts, DHF-based materials can be chemically recycled and naturally degrade in the environment.

Related Stories

“The whole process, from creating to reusing, is more environmentally friendly than current materials,” said Reagan Dreiling, a doctoral student in chemistry and first author of the paper published in Nature.

By applying ROMP and cationic polymerization in a single step, the researchers created a thermoset with tunable properties. The process allows precise control over polymer density and structure, making it suitable for applications in aerospace, biomedical devices, and industrial coatings.

Recycling and Environmental Impact

One of the most promising aspects of DHF thermosets is their ability to be broken down and reformed into their original monomer. Unlike traditional plastics, which degrade into microplastics that persist in ecosystems, DHF-based thermosets degrade into non-toxic components.

In laboratory experiments, researchers demonstrated that heating the material allows it to be reprocessed, offering a true circular economy for plastics. Additionally, exposure to environmental conditions led to natural degradation, reducing the risk of long-term pollution.

“We’ve spent 100 years trying to make polymers that last forever, and we’ve realized that’s not actually a good thing,” Fors said. “Now we’re making polymers that don’t last forever, that can environmentally degrade.”

The ability to degrade and recycle thermosets could revolutionize industries reliant on durable plastics. The researchers are now working on expanding the applications of this material, including making it compatible with 3D printing. By modifying the DHF monomer and exploring additional polymerization strategies, they hope to enhance its properties and broaden its industrial use.

Toward a Sustainable Future

The discovery of a recyclable thermoset marks a significant step toward reducing plastic waste and dependence on petroleum-based materials. By utilizing bio-based monomers, the Cornell team has developed an alternative that maintains durability while addressing the need for sustainability.

In contrast to conventional plastics, which require energy-intensive recycling methods or persist indefinitely, DHF thermosets provide a practical and scalable solution. Their chemical recyclability and environmental degradation align with the push toward sustainable materials in manufacturing.

As researchers refine this technology, industries that rely on thermosets—such as automotive, aerospace, and biomedical sectors—could transition to greener alternatives without compromising performance. With continued innovation, materials like DHF-based thermosets could lead to a more sustainable future for plastics, reducing pollution and conserving resources.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer | AI and Robotics Reporter

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a contributor to The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business Administration at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.