Revolutionary process vaporizes plastic bags and bottles to create new, recycled plastics

A new process developed at UC Berkeley can turn plastic waste into reusable building blocks for new plastics, paving the way for a sustainable, circular economy for hard-to-recycle polyethylene and polypropylene plastics.

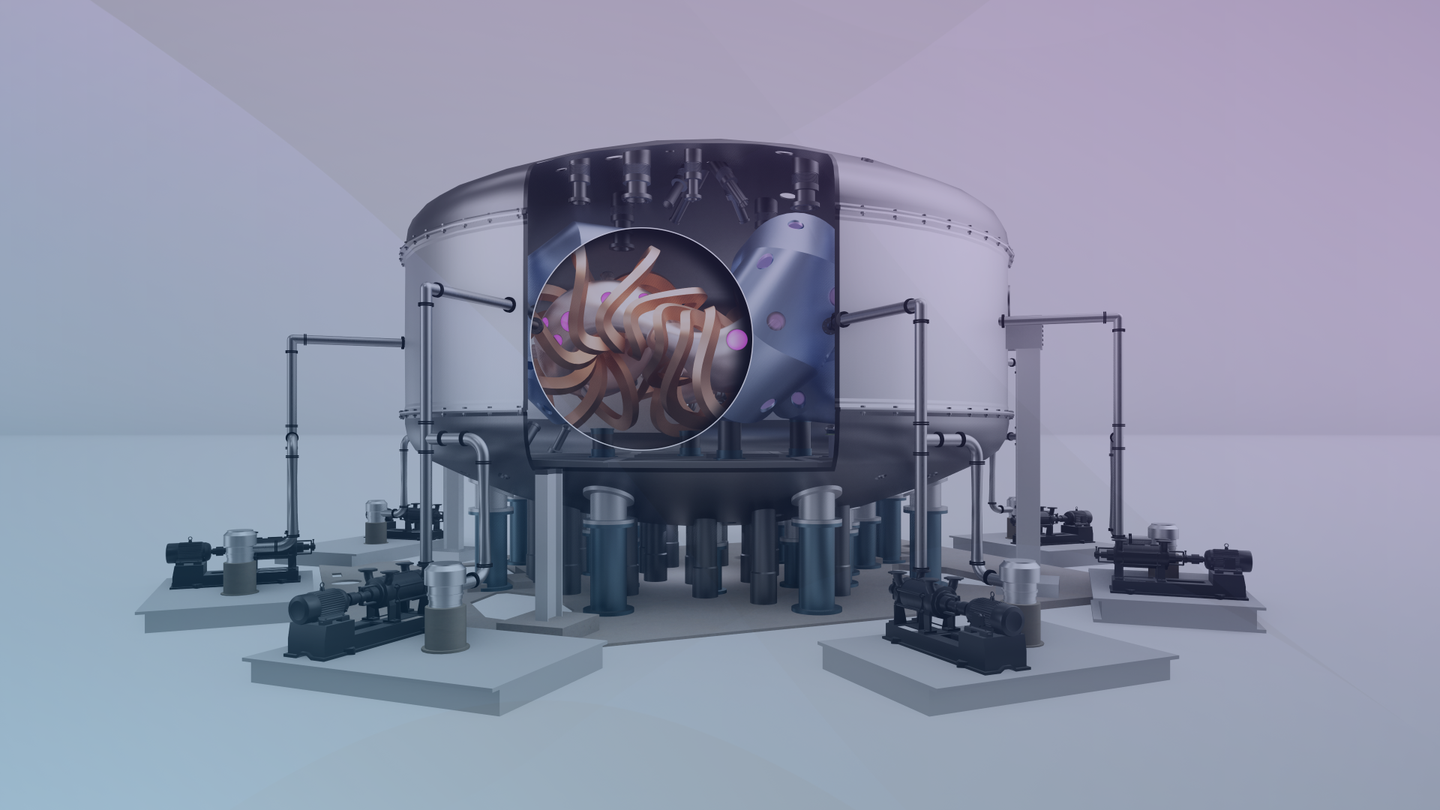

Graduate student RJ Conk adjusts a reaction chamber in which mixed plastics are degraded into the reusable building blocks of new polymers. (CREDIT: Robert Sanders/UC Berkeley)

A groundbreaking chemical process developed at the University of California, Berkeley, could transform plastic waste into valuable hydrocarbon building blocks for creating new plastics. This innovative approach holds promise for addressing the growing environmental impact of plastic waste and offers a potential path toward a circular economy for plastics.

The process is designed to degrade two of the most common types of post-consumer plastic waste: polyethylene and polypropylene. Polyethylene is widely used in single-use plastic bags, while polypropylene is found in products such as microwavable dishes and luggage. Remarkably, the process is also effective at breaking down mixtures of these plastics, which dominate global waste streams.

The idea behind this research is to recycle these hard-to-decompose plastics into their original monomer forms. By doing so, these plastics can be reused to create new materials, significantly reducing the reliance on fossil fuels and limiting the need for producing new plastics from petroleum.

“We have an enormous amount of polyethylene and polypropylene in everyday objects, from lunch bags to laundry soap bottles to milk jugs—so much of what’s around us is made of these polyolefins,” said John Hartwig, a professor of chemistry at UC Berkeley, who led the research.

“What we can now do, in principle, is take those objects and bring them back to the starting monomer by chemical reactions we’ve devised that cleave the typically stable carbon-carbon bonds. By doing so, we’ve come closer than anyone to give the same kind of circularity to polyethylene and polypropylene that you have for polyesters in water bottles,” he continued.

The Path to a Circular Economy

Plastic waste, especially polyethylene and polypropylene, makes up a staggering two-thirds of post-consumer waste globally. Of that waste, around 80% either ends up in landfills, is incinerated, or is irresponsibly discarded, ultimately contributing to the growing issue of microplastics in waterways and oceans. The remainder is recycled into low-value items such as flowerpots and other non-essential products, which does little to address the root of the waste problem.

Researchers have been searching for more valuable ways to reuse plastic waste, aiming to create a circular polymer economy. In this ideal scenario, plastic waste is repurposed into monomers that can be re-polymerized to form new plastics. This reduces the need for new plastics derived from petroleum, which is both expensive and a significant source of greenhouse gas emissions.

Two years ago, Hartwig’s team made a significant leap toward this goal by developing a process to break down polyethylene bags into propylene, the primary ingredient for polypropylene plastics. However, the process at that time required expensive, soluble metal catalysts that had limited lifespan and were difficult to recover in an active form.

Related Stories

In their latest breakthrough, the researchers have replaced these costly catalysts with more economical and durable solid catalysts commonly used in the chemical industry. Solid catalysts are well-suited for continuous flow processes, which can handle large volumes of material and reuse catalysts, making the process more scalable for industrial applications.

How the New Process Works

The key to this process lies in a combination of two catalysts: sodium on alumina and tungsten oxide on silica. Richard J. "RJ" Conk, a graduate student in Hartwig’s lab, first experimented with these catalysts after consulting with chemical engineer Alexis Bell, an expert in heterogeneous catalysts at UC Berkeley.

Sodium on alumina was found to be particularly effective at breaking down polyolefin chains, while tungsten oxide on silica played a crucial role in transforming these chains into propylene. The latter process, known as olefin metathesis, continues to add carbon atoms from ethylene gas until the polymer chain is fully converted into propylene.

Interestingly, tungsten oxide proved even more effective than sodium for breaking polypropylene chains, yielding a combination of propene and isobutylene. These hydrocarbon products are not only valuable in the production of new polymers but also have various applications in the chemical industry, including the manufacture of high-octane gasoline additives.

“You can’t get much cheaper than sodium,” Hartwig noted. “And tungsten is an earth-abundant metal used in the chemical industry on a large scale, as opposed to our previous ruthenium metal catalysts that were more sensitive and more expensive. This combination of tungsten oxide on silica and sodium on alumina is like taking two different types of dirt and having them together disassemble the whole polymer chain.”

Tackling Tough Plastics

One of the major challenges with polyethylene and polypropylene plastics is their stability. Unlike polyester plastics, which can be easily recycled because of their reactive carbon-oxygen bonds, polyolefins have strong carbon-carbon bonds that are difficult to break. Hartwig likened these plastics to a "string of pearls," with the challenge being how to snip the string in the middle so that each individual "pearl" could be removed one at a time.

The new catalytic process circumvents this challenge by creating reactive carbon-carbon double bonds at the end of polymer chains, allowing the catalysts to access and deconstruct the chain repeatedly until it is fully broken down.

Conk also tested the process with various plastic additives and contaminants. While small amounts of impurities had little impact on the efficiency of the reaction, materials like PET and polyvinyl chloride (PVC) significantly reduced the yield. However, this issue may be mitigated by current plastic recycling methods, which already involve sorting different types of plastics.

As the global demand for plastics continues to grow, the need for sustainable recycling solutions becomes increasingly urgent. While some argue that all polyethylene and polypropylene should be phased out in favor of new, easily recyclable materials, Hartwig acknowledges that such a shift is unlikely to happen for decades. Polyolefins are cheap, versatile, and widely used, meaning that a solution for recycling these materials is critical for long-term sustainability.

“One can argue that we should do away with all polyethylene and polypropylene and use only new circular materials,” Hartwig said. “But the world’s not going to do that for decades and decades. Polyolefins are cheap, and they have good properties, so everybody uses them. People say if we could figure out a way to make them circular, it would be a big deal, and that’s what we’ve done.”

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer | AI and Robotics Reporter

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a contributor to The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business Administration at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.