Revolutionary heat pump directly converts electricity into heat

Air conditioning and refrigeration systems are energy-intensive, noisy, and contribute to greenhouse gas emissions.

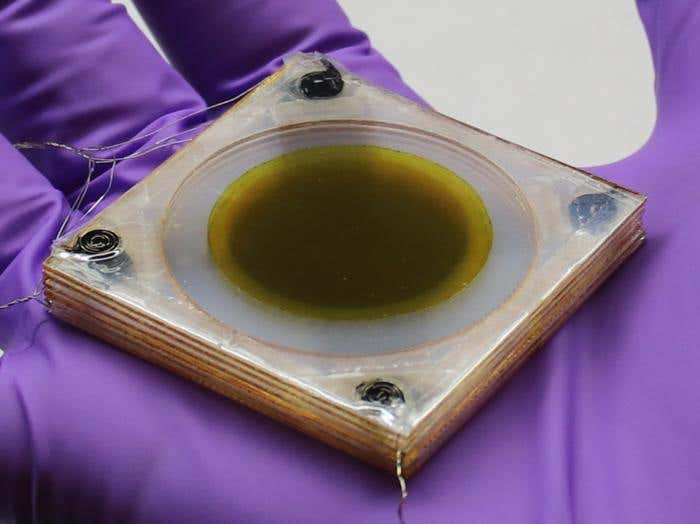

Explore how the self-regenerative heat pump uses advanced polymer films to achieve efficient, eco-friendly cooling without greenhouse gas emissions. (CREDIT: UCLA Soft Materials Research Laboratory)

Air conditioning and refrigeration consume about 20% of global electricity, relying on century-old vapor-compression technologies. These systems are energy-intensive, noisy, and contribute to greenhouse gas emissions. To combat these challenges, researchers are exploring innovative solid-state cooling alternatives.

Among them, the electrocaloric (EC) effect stands out, offering a direct method to convert electricity into heat. Published in the journal, Science, scientists are now leveraging this phenomenon to create a groundbreaking self-regenerative heat pump (SRHP) that operates without fluids or complex mechanisms, revolutionizing cooling technology.

The EC effect involves a reversible entropy change in specific materials when subjected to an electric field, causing a temperature shift. Poly(vinylidene fluoride-ter-trifluoroethylene-ter-chlorofluoroethylene), or P(VDF-TrFE-CFE), is a polymer exhibiting a giant EC effect at room temperature. Its molecular structure allows significant dipole reorientation, which translates to substantial temperature changes under an electric field.

When an electric field is applied, the polymer’s molecular chains align, decreasing entropy and releasing heat. Conversely, removing the field restores the original molecular arrangement, absorbing heat and lowering the material’s temperature. These rapid, reversible transformations make P(VDF-TrFE-CFE) a promising candidate for cooling applications.

The polymer’s properties are enhanced by its mechanical flexibility, which supports the seamless integration into compact devices. The material also boasts a Young’s modulus of 133 MPa, demonstrating its mechanical resilience. This combination of thermal and mechanical properties sets P(VDF-TrFE-CFE) apart as a pivotal material in solid-state cooling technologies.

The SRHP is a cascade system comprising six-unit devices, each containing stacked polymer films. These films are coated with carbon nanotube electrodes and separated by polyimide (PI) layers, which ensure mechanical stability and optimize deformation under an electric field. The PI layers enable the film stacks to achieve regular out-of-plane deformations, critical for efficient heat transfer.

When an electric field of 80 MV/m is applied, the polymer films compress, transferring heat to adjacent stacks. As the field alternates, the stacks expand and cool, creating a continuous heat-pumping cycle. The cascade design ensures a unidirectional heat flow, reducing ambient temperatures by up to 14 K. Infrared thermal imaging confirms the system’s rapid temperature response, with each cycle completing in approximately 30 seconds.

The SRHP operates on a simple yet effective principle. In its six-stack arrangement, alternating stacks are activated in opposite phases. This antiphase operation ensures continuous thermal contact between the active and inactive stacks. Heat is transported from the cooling platform at the top to the aluminum heat sink at the base, creating a sustained temperature gradient.

Related Stories

A critical design feature is the spacing between the film stacks, set at 0.95 mm—slightly less than the vertical stroke at 80 MV/m. This precise spacing ensures smooth thermal contact without buckling, optimizing heat transfer. Additionally, the device’s modular structure allows scalability for varying cooling needs.

The SRHP’s compact design delivers remarkable efficiency. Laboratory tests demonstrated a specific cooling power of 1.52 watts per gram, outperforming traditional cooling methods. Its rapid response time, minimal energy consumption, and absence of greenhouse gas emissions highlight its potential as an eco-friendly alternative to vapor-compression systems.

“Our long-term goal is to develop this technology for wearable cooling accessories that are comfortable, affordable, reliable, and energy-efficient,” said Qibing Pei, a materials science professor at UCLA. Such devices could benefit individuals working in extreme heat, providing localized cooling with minimal energy requirements.

The polymer’s flexibility and lightweight nature make it ideal for wearable applications and portable devices. Unlike conventional systems, the SRHP’s operation is entirely solid-state, eliminating the need for fluids or moving parts. This simplicity reduces manufacturing complexity and maintenance costs, paving the way for widespread adoption.

The absence of fluids also enhances the device’s reliability, as there are fewer components prone to wear or failure. This reliability is particularly advantageous in remote or demanding environments where traditional cooling systems might falter. The SRHP’s ability to operate efficiently under a wide range of conditions further extends its versatility.

Developing a practical EC cooling device involves addressing several challenges. One key limitation is the modest temperature change (ΔTECE) achievable by EC materials. The SRHP’s cascading design compensates for this by amplifying the temperature differential across multiple stages. Additionally, the PI backing layer mitigates issues like irregular buckling, ensuring consistent performance.

Ambient conditions also influence the SRHP’s effectiveness. For instance, at lower temperatures, the ΔTECE values slightly decrease. At 12°C, the temperature change is 3.45 K, compared to 4.42 K at 22°C. Researchers are exploring material modifications to enhance performance across broader temperature ranges.

Moreover, scaling the technology for industrial applications presents engineering challenges. Larger systems require precise synchronization of the electric field cycles and robust thermal management. Collaborative efforts among engineers and materials scientists are crucial to overcoming these hurdles and unlocking the technology’s full potential.

The SRHP represents a significant leap in solid-state cooling technology. Its ability to achieve substantial temperature reductions without complex mechanisms positions it as a viable solution for diverse applications. From wearable cooling accessories to advanced electronics and portable refrigeration, the potential uses are vast.

“This cooling device integrates advanced materials with an elegant mechanical architecture to deliver energy-efficient cooling,” noted Wenzhong Yan, a postdoctoral researcher in mechanical engineering. With continued innovation, the SRHP could transform industries reliant on traditional cooling methods.

The technology’s environmental benefits are equally noteworthy. Operating solely on electricity, the SRHP aligns with renewable energy goals, offering a sustainable alternative to systems reliant on refrigerants. By reducing energy consumption and eliminating greenhouse gas emissions, this innovation addresses critical climate challenges.

The SRHP’s adaptability also makes it a strong candidate for emerging markets. For example, wearable cooling systems could revolutionize industries such as healthcare, sports, and construction, providing individuals with localized temperature control. In electronics, the technology could prevent overheating in devices with flexible components, ensuring optimal performance.

The research team’s efforts, supported by institutions like the U.S. Office of Naval Research and Lawrence Berkeley National Laboratory, underscore the importance of interdisciplinary collaboration in advancing cooling technologies.

With ongoing refinement, the SRHP could become a cornerstone of next-generation thermal management systems, paving the way for a cooler, more sustainable future.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer | AI and Robotics Reporter

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a contributor to The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business Administration at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.