Revolutionary engine has no moving parts and is more efficient than a steam turbine

TPV cells convert heat to electricity at 40% efficiency, paving the way for thermal battery systems that store renewable energy

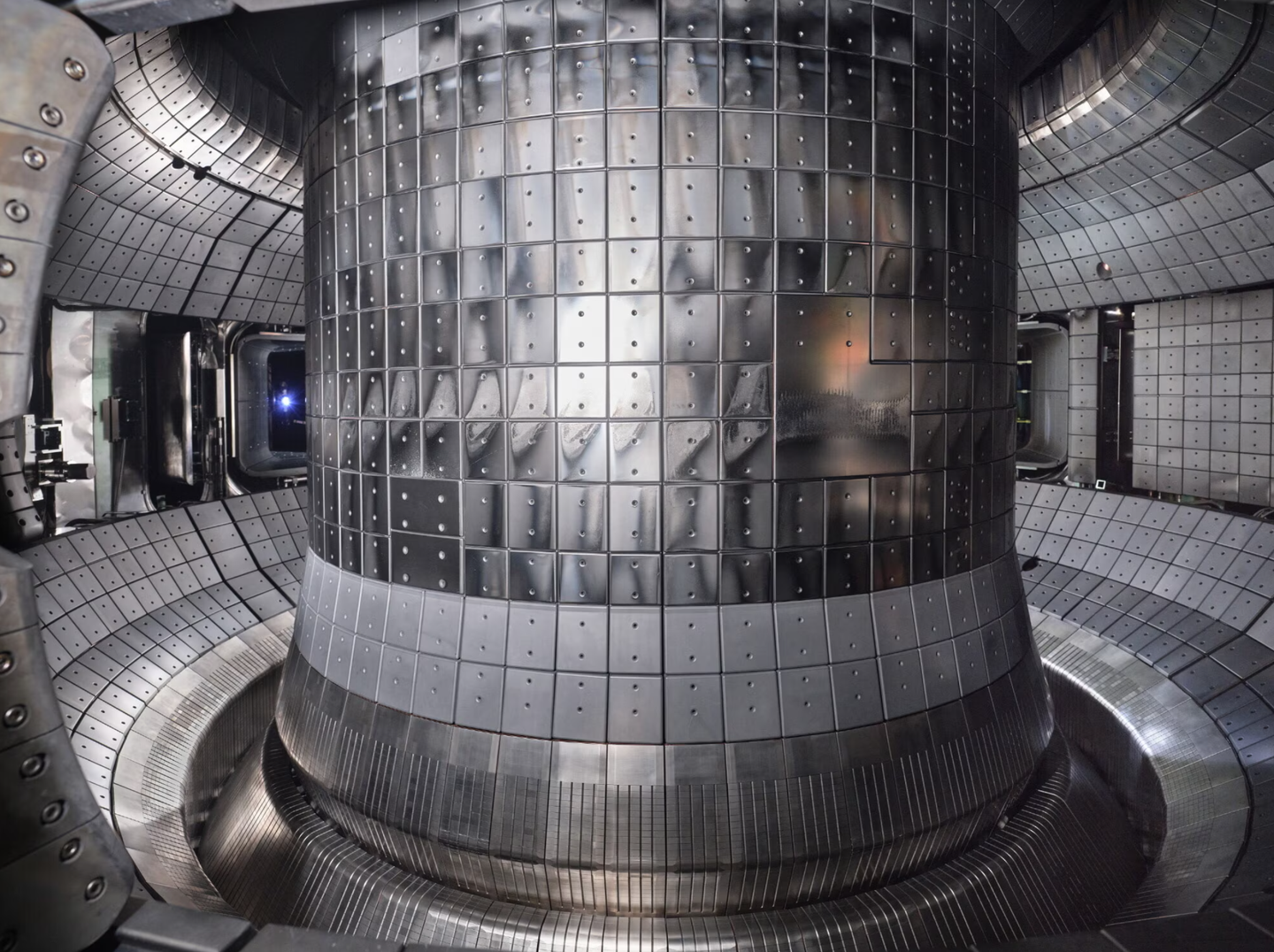

Engineers at MIT and NREL have developed a heat engine with no moving parts that is as efficient as a steam turbine. (CREDIT: Felice Frankel)

Researchers from MIT and the National Renewable Energy Laboratory (NREL) have developed an innovative heat engine that uses no moving parts, making a significant leap toward more efficient renewable energy systems.

The team’s thermophotovoltaic (TPV) cell converts heat into electricity with over 40% efficiency, surpassing the performance of traditional steam turbines, which have long been the standard for generating electricity from heat.

This TPV cell, much like the photovoltaic cells in solar panels, passively captures photons from extremely hot sources, converting them into electricity. The cell can operate with heat sources ranging from 1,900 to 2,400 degrees Celsius (3,450 to 4,350 degrees Fahrenheit). Such temperatures exceed the limits of traditional steam turbines, which rely on moving parts that can degrade at higher temperatures.

One of the main goals for the researchers is to integrate these TPV cells into a grid-scale thermal battery system. The concept involves storing excess energy from renewable sources, such as solar power, in heavily insulated banks of heated graphite.

On days when renewable energy sources are less available—like cloudy or windless days—the TPV cells would convert the stored heat back into electricity. This energy could then be dispatched to power grids, helping to stabilize and decarbonize the energy supply.

According to Asegun Henry, a key researcher and the Robert N. Noyce Career Development Professor at MIT, the TPV cell marks a crucial step forward in developing thermal batteries. “Thermophotovoltaic cells were the last key step toward demonstrating that thermal batteries are a viable concept,” Henry said. The research was recently published in Nature, with a team of co-authors from MIT and NREL.

Steam turbines, which are widely used today, convert about 35% of heat into electricity on average, with the most efficient models reaching around 60%. However, they depend on complex machinery with moving parts that limit their ability to operate at high temperatures.

Related Stories

The TPV system, being solid-state, has no such moving parts. This not only makes it more durable but also reduces maintenance costs. As Henry points out, "One of the advantages of solid-state energy converters is that they can operate at higher temperatures with lower maintenance costs because they have no moving parts. They just sit there and reliably generate electricity."

Over 90% of the world’s electricity currently comes from heat-based sources, such as coal, nuclear energy, natural gas, and concentrated solar energy. Since steam turbines have dominated the industry for a century, alternatives like the TPV cell offer a promising path toward a more sustainable energy future. The new design aims to operate in much hotter environments than steam turbines can handle, making it ideal for next-generation thermal battery systems that store renewable energy.

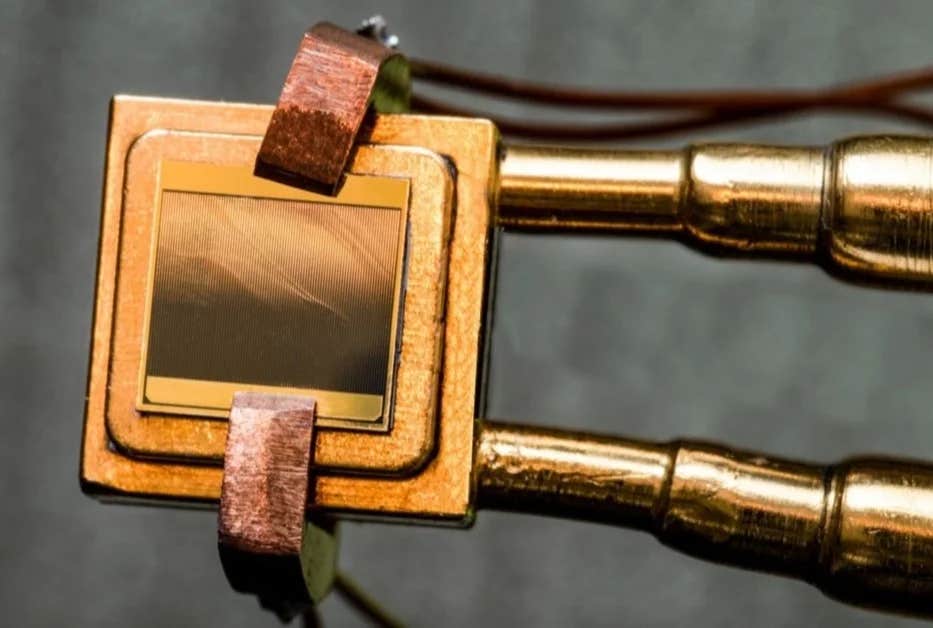

TPV cells operate on a similar principle as solar cells: they absorb photons with enough energy to move electrons across a bandgap in the cell’s material, generating electricity. However, until now, most TPV cells had low conversion efficiencies, reaching only about 20% to 32%. These older cells used materials with lower bandgaps that could only capture lower-energy photons, limiting their overall effectiveness.

Henry and his colleagues have made significant progress in overcoming these limitations. Their new TPV design uses materials with higher bandgaps and multiple layers, or junctions, to capture photons from higher-temperature heat sources.

The cell is built with three key layers. The first, made of a high-bandgap alloy, captures the highest-energy photons from the heat source. A second, slightly lower-bandgap alloy beneath it captures photons that pass through the first layer. Finally, a mirror-like layer of gold reflects any photons that escape the second layer back to the heat source, preventing energy loss.

The team tested the cell’s efficiency by exposing it to high-temperature light and measuring how well it converted the heat into electricity. Remarkably, the TPV cell maintained around 40% efficiency across a temperature range of 1,900 to 2,400 degrees Celsius. "We can get a high efficiency over a broad range of temperatures relevant for thermal batteries," said Henry, emphasizing the potential for this technology to work across different operating conditions.

Scaling up this technology for grid-scale use would require TPV cells to cover large areas. Henry estimates that about 10,000 square feet (approximately a quarter of a football field) of TPV cells would be needed for a thermal battery system capable of serving power grids. These cells could be manufactured using the existing infrastructure for photovoltaic solar panels, further reducing costs and complexity in bringing the technology to market.

In addition to its efficiency and scalability, the TPV system is environmentally friendly. Henry emphasized that the technology is both safe and sustainable, with significant potential to reduce carbon dioxide emissions from electricity production.

“There’s definitely a huge net positive here in terms of sustainability,” he said. “The technology is safe, environmentally benign in its life cycle, and can have a tremendous impact on abating carbon dioxide emissions from electricity production.”

This breakthrough could pave the way for more resilient and decarbonized energy systems, especially as the world increasingly turns to renewable energy to combat climate change. With the successful demonstration of the TPV cell, Henry and his team are now working to integrate it into a fully operational thermal battery system that could one day replace fossil-fuel-based power plants.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.