Reshaping sustainable energy: Converting CO2 into valuable chemicals and fuels

The mounting challenges of climate change, fueled by rising atmospheric CO2 levels from fossil fuel consumption, demand innovative solutions.

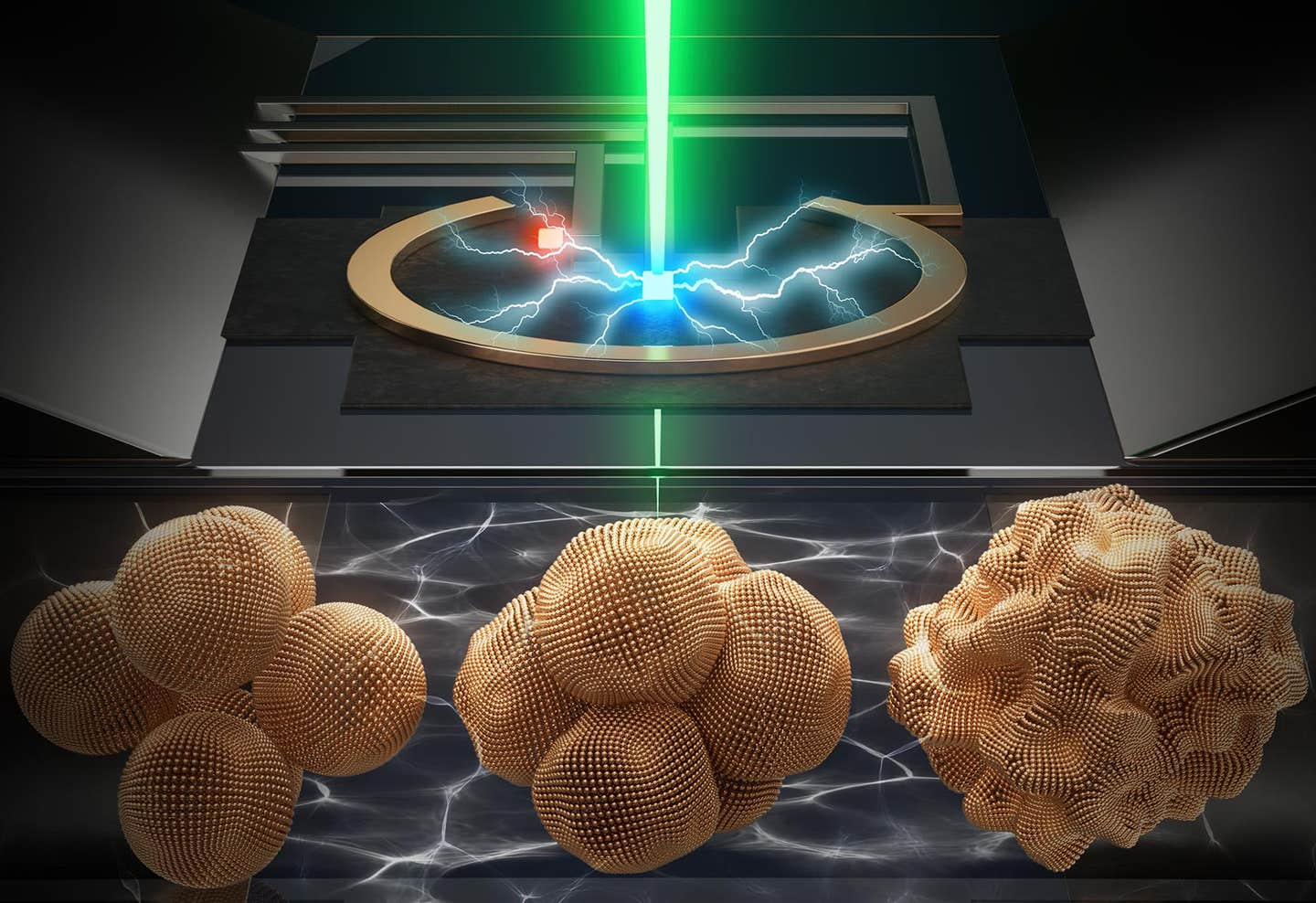

Artist’s rendering of a copper nanoparticle as it evolves during CO2 electrolysis. (CREDIT: Berkeley Lab)

The mounting challenges of climate change, fueled by rising atmospheric CO2 levels from fossil fuel consumption, demand innovative solutions. Among these, the CO2 electroreduction reaction (CO2RR) has garnered attention for its potential to convert CO2 into valuable chemicals and fuels, effectively closing the carbon cycle.

Yet, its widespread adoption has been hindered by issues of selectivity and stability, particularly with conventional copper-based catalysts. Recent research published in the Journal of Energy and Environmental Sciences, however, has introduced a breakthrough that could reshape the field and accelerate progress toward sustainable energy solutions.

By employing a combination of copper and zinc oxide in a pulsed electrochemical CO2RR, scientists have achieved a remarkable leap in catalyst performance. This novel approach enhances ethanol production while reducing undesirable by-products such as hydrogen.

The findings reveal how zinc oxide coatings on copper nanocubes stabilize the catalyst and optimize reaction conditions, paving the way for more efficient and sustainable CO2 conversion processes. This development represents a significant step forward in both the science of catalysis and the global effort to combat climate change.

Innovation in Catalyst Design

Traditionally, CO2 electroreduction relied on copper-based catalysts operating under stationary conditions. While effective, these systems struggled with limited ethanol selectivity and stability. The incorporation of pulsed CO2RR changes this dynamic by introducing precise control over the redox states of the catalytic metals.

Researchers discovered that when the zinc component undergoes oxidation, it protects the copper from degradation, significantly improving the catalyst’s durability. This protective mechanism extends the lifetime of the catalyst under demanding conditions, enabling prolonged and efficient operation.

Zinc oxide’s role extends beyond stabilization. It enhances ethanol production by promoting interactions between adsorbed hydroxide and carbon monoxide intermediates, critical steps in the formation of alcohol products. This improvement in selectivity is particularly important for the production of ethanol, a widely used fuel and industrial chemical.

Related Stories

Time-resolved operando techniques, such as Raman spectroscopy and X-ray diffraction, provided real-time insights into these dynamic processes. These advanced tools revealed how zinc oxide transitions into different states, influencing the catalyst’s composition and performance. The ability to monitor these changes in real time offers an unprecedented understanding of how to optimize bimetallic systems for CO2 reduction.

Advanced Techniques Reveal Key Mechanisms

Understanding the interplay of materials during CO2RR is essential for optimizing catalyst design. Using operando Raman spectroscopy, researchers tracked the structural and chemical changes of ZnO-decorated Cu2O nanocubes under pulsed conditions.

This sensitive method detected key intermediates adsorbed onto the catalyst surface, shedding light on the reaction mechanisms. The combination of real-time observations and precise experimental control allows researchers to tailor the catalytic process to maximize efficiency and selectivity.

The study demonstrated that pulsing the system into the oxidation regime of zinc enhances ethanol selectivity. Conversely, pushing copper into its oxidation regime increases parasitic hydrogen evolution, reducing efficiency. This balance underscores the importance of controlling the redox states of both metals to achieve optimal performance.

The findings highlight the synergy between copper and zinc, with each element contributing uniquely to the catalytic process. This insight could lead to the development of new materials and strategies for a wide range of applications beyond CO2 reduction.

Towards a Sustainable Future

The implications of this research extend far beyond ethanol production. By addressing long-standing issues of selectivity and stability in CO2RR, this innovation supports global efforts to reduce carbon emissions and develop renewable energy solutions.

The ability to create more durable and efficient catalysts aligns with the push for green technologies in the fight against climate change. These findings represent not only a technical achievement but also a step toward achieving global sustainability goals.

This approach also opens doors for further advancements in bimetallic catalyst systems. The principles established here could inspire similar strategies in the production of other valuable chemicals, broadening the impact of CO2RR technologies.

The adaptability of this method suggests its potential for scaling to industrial applications, making it a viable solution for addressing large-scale environmental challenges. As the world seeks to transition to sustainable energy sources, innovations like this will play a crucial role in shaping a cleaner, greener future.

The collaboration of advanced scientific methods and innovative design principles has enabled this breakthrough. Researchers’ ability to observe and manipulate the dynamic interplay of materials in real time offers a new level of control over catalytic processes.

This capability will likely drive further discoveries in related fields, reinforcing the importance of multidisciplinary approaches to solving complex global problems.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer | AI and Robotics Reporter

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a contributor to The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business Administration at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.