Researchers develop the world’s first carbon-negative concrete

The new formula could have a significant impact on the carbon emissions produced by the concrete industry, one of the most carbon-intensive.

[Apr. 19, 2023: JD Shavit, The Brighter Side of News]

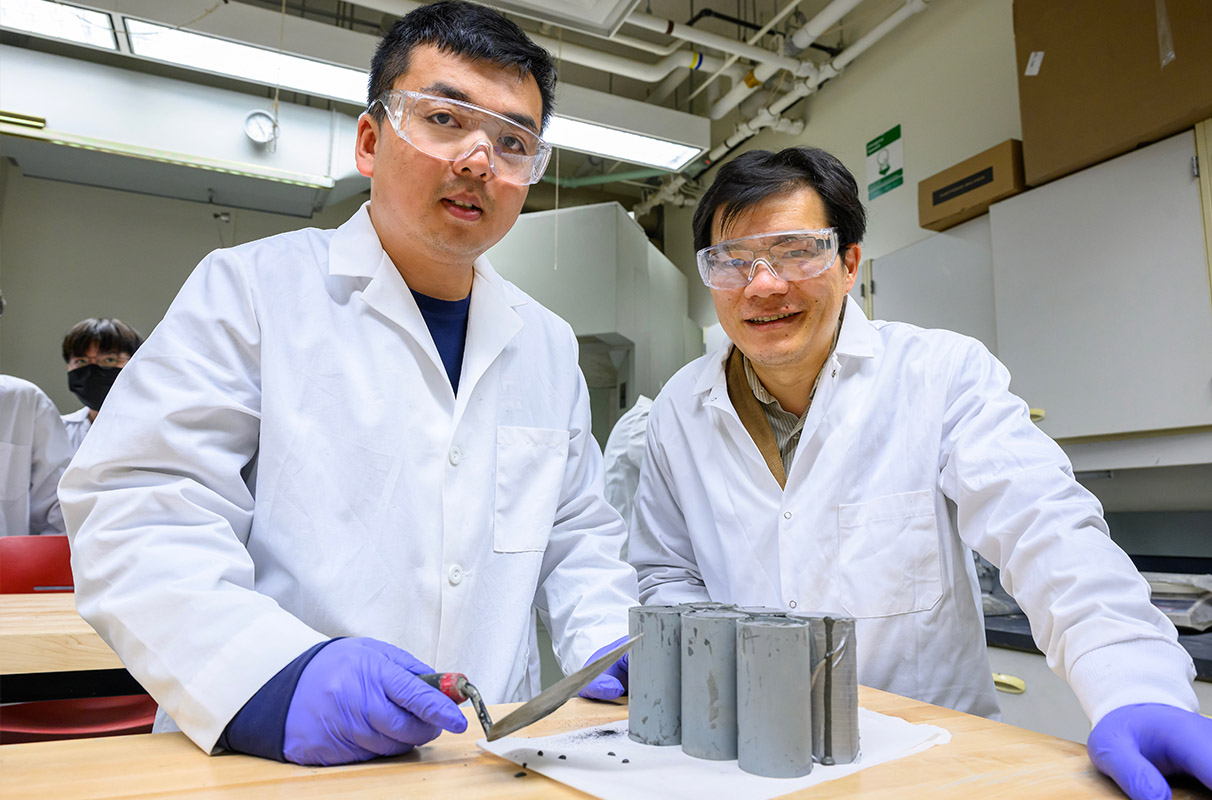

Graduate student Zhipeng Li and Professor Xianming Shi. (CREDIT: Washington State University)

A team of researchers from Washington State University (WSU) has developed a formula for a carbon-negative, environmentally friendly concrete that is nearly as strong as regular concrete. The new formula could have a significant impact on the carbon emissions produced by the concrete industry, which is known to be one of the most energy- and carbon-intensive of all manufacturing industries.

According to the researchers, the key to the breakthrough lies in the use of biochar, a type of charcoal made from organic waste that is known for its ability to absorb carbon dioxide from the atmosphere. In their proof-of-concept work, the researchers infused regular cement with biochar that had been strengthened with concrete wastewater, a type of waste material produced during concrete production.

The researchers found that the biochar was able to absorb up to 23% of its weight in carbon dioxide from the air while still achieving a strength comparable to that of ordinary cement. The research was led by doctoral student Zhipeng Li and is reported in the journal, Materials Letters.

“We’re very excited that this will contribute to the mission of zero-carbon built environment,” said Xianming Shi, professor in the WSU Department of Civil and Environmental Engineering and the corresponding author on the paper.

Related Stories:

The production of ordinary cement is known to be a major contributor to global carbon emissions. It requires high temperature and combustion of fuels, and the limestone used in its production goes through decomposition which produces carbon dioxide. Cement production is thought to be responsible for about 8% of total carbon emissions by human activities worldwide.

Researchers have tried adding biochar as a substitute in cement to make it more environmentally friendly and reduce its carbon footprint, but adding even 3% of biochar dramatically reduced the strength of the concrete. However, after treating biochar in the concrete washout wastewater, the WSU researchers were able to add up to 30% biochar to their cement mixture. The paste made of the biochar-amended cement was able to reach a compressive strength after 28 days comparable to that of ordinary cement of about 4,000 pounds per square inch.

“The trick is really in the interfacial engineering – how you engineer the interfaces in the concrete,” said Shi. “We’re committed to finding novel ways to divert waste streams to beneficial uses in concrete; once we identify those waste streams, the next step is to see how we can wave the magic wand of chemistry and turn them into a resource.”

Global potential for agricultural-based greenhouse gas mitigation practices, where biochar application considers a global mitigation potential of 1.0–1.8 Gt CO2–C equivalent per year. (Adapted from Paustian et al. (2016))

The researchers used the calcium in the concrete washout water to induce the formation of calcite, which benefits the biochar and eventually the concrete incorporating the biochar. The synergy between the highly alkaline wastewater that contains a lot of calcium and the highly porous biochar meant that calcium carbonate precipitated onto or into the biochar, strengthening it and allowing for the capture of carbon dioxide from the air.

“Most other researchers were only able to add up to 3% biochar to replace cement, but we’re demonstrating the use of much higher dosages of biochar because we’ve figured out how to engineer the surface of the biochar,” said Shi.

The life cycle assessment confirmed that the biochar incorporation significantly reduced CO2 emissions, and most importantly, the combined use of biochar and SCMs successfully achieved carbon-negative concrete production. (CREDIT: Washington State University)

A concrete made of the material would be expected to continue sequestering carbon dioxide for the lifetime of the concrete, typically 30 years in pavement or 75 years in a bridge. In order to commercialize this technology, the researchers have been working with the Office of Commercialization to protect the intellectual property and have filed a provisional patent application on their carbon-negative concrete work.

They recently received a seed grant from the Washington Research Foundation to produce more data for a variety of use cases. They are also actively seeking industry partners from the building and construction sector to scale up production for field demonstrations and licensing this WSU technology.

For more science news stories check out our New Innovations section at The Brighter Side of News.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.

Joseph Shavit

Head Science News Writer | Communicating Innovation & Discovery

Based in Los Angeles, Joseph Shavit is an accomplished science journalist, head science news writer and co-founder at The Brighter Side of News, where he translates cutting-edge discoveries into compelling stories for a broad audience. With a strong background spanning science, business, product management, media leadership, and entrepreneurship, Joseph brings a unique perspective to science communication. His expertise allows him to uncover the intersection of technological advancements and market potential, shedding light on how groundbreaking research evolves into transformative products and industries.