Researchers develop fully-recyclable plastic to solve the global plastic waste crisis

Per researchers, almost 6 billion metric tons of plastic waste have been produced globally, with less than 10% of it being recycled.

[Apr. 2, 2023: Staff Writer, The Brighter Side of News]

This new recyclable plastic is made from the same raw ingredient as Super Glue and could potentially provide a competitive alternative to traditional plastics. (CREDIT: Science Advances)

Boise State University researchers, Allison Christy and Scott Phillips, have developed a new type of plastic that could be the solution to the global plastic waste crisis. This new recyclable plastic is made from the same raw ingredient as Super Glue and could potentially provide a competitive alternative to traditional plastics.

According to the researchers, almost 6 billion metric tons of plastic waste have been produced globally, with less than 10% of it being recycled. Additionally, the raw materials used to make plastic come from fossil fuels, further contributing to environmental problems. The need for an alternative solution has never been more pressing.

The new plastic, called polyethyl cyanoacrylate (PECA), can be recycled into clean beginning materials in around 93% of the new plastic, according to small-scale lab trials that mimic industrial operations.

The researchers predict that if produced at industrial proportions, the new recyclable plastic PECA material might take the place of polystyrene plastics, which are not acceptable in the majority of curbside recycling programs.

Related Stories

Polystyrene plastics only make up 6% of the current plastic waste, which is a minor portion of a much bigger issue. However, Christy and Phillips believe that eventually, their new recyclable plastic could provide a competitive alternative to plastics other than polystyrene.

The PECA plastic has qualities similar to those of conventional polymers and remains stable in hot, humid settings, according to early laboratory testing by Christy and Phillips. The researchers demonstrated how the lengthy polymer chains of PECA plastic may be thermally "cracked" at 210 °C, with the resultant monomers being distilled into something similar to a clean product for reuse.

Recycling plastics is a good concept, but for consumers to support it, the proper procedures must be in place. In Norway, programs have been implemented that have resulted in 97% of plastic bottles being recycled. It is crucial to have effective systems in place to ensure that plastic waste is recycled effectively.

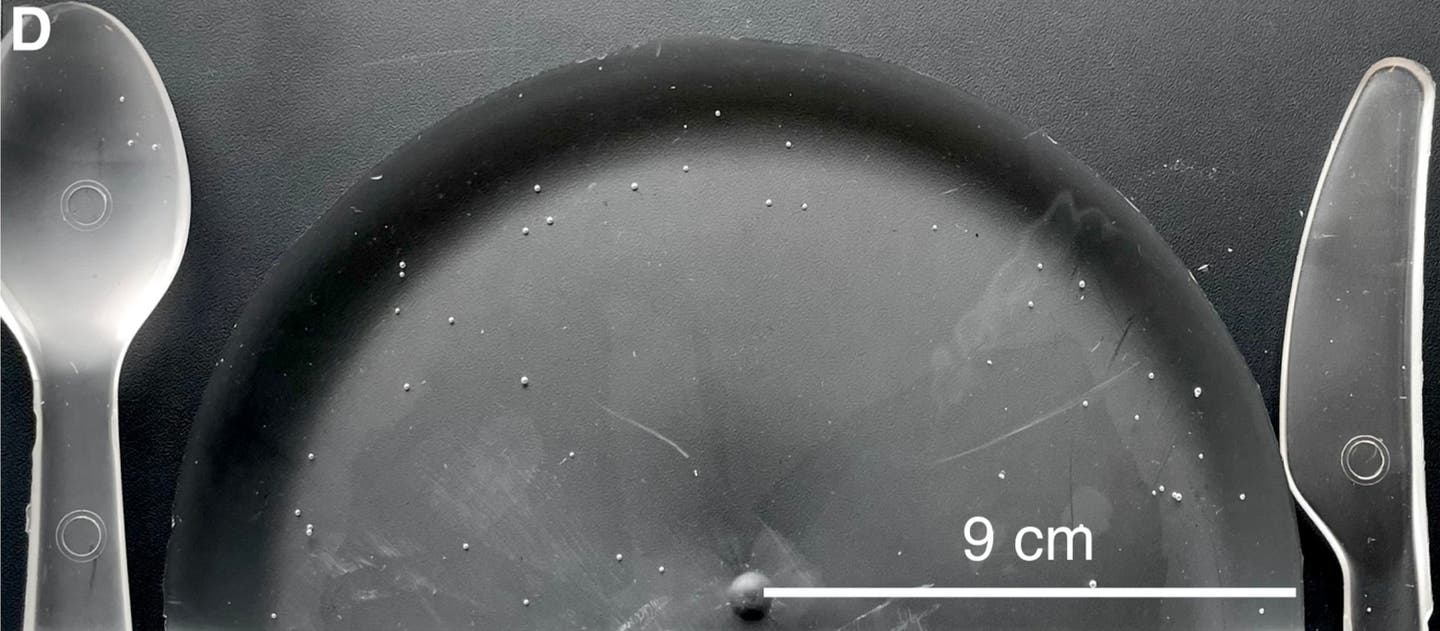

Plastic cutlery made from PECA. (CREDIT: Allison Christy/Boise State University)

The plastic waste crisis is not just an environmental issue, but also an economic and social one. The cost of cleaning up plastic waste and the impact on the tourism and fishing industries are significant. Additionally, plastic waste harms marine life, and plastic pollution affects human health.

The new recyclable plastic developed by Christy and Phillips has the potential to address these issues. The researchers are optimistic about the potential of their new plastic and believe that it could make a significant difference in the fight against plastic waste.

Christy and Phillips' study was recently published in the journal Science Advances, where they describe the creation of a new kind of plastic based on polyethyl cyanoacrylate, which is made from the same monomer as Super Glue. The researchers hope that their new recyclable plastic will eventually provide a competitive alternative to traditional plastics.

Direct polymerization and casting of ethyl cyanoacrylate. (CREDIT: Science Advances)

The production of PECA is not yet at an industrial scale, and there is still much work to be done. However, the potential benefits of this new plastic are promising. As the world grapples with the plastic waste crisis, it is vital to explore new solutions to address this critical issue. The development of the new recyclable plastic by Christy and Phillips is a significant step in the right direction.

Other recyclable plastics under development

The issue with conventional plastics is that they are often made from non-renewable fossil fuels and are not biodegradable, leading to significant environmental concerns. However, researchers have been working on developing new types of plastics that are not only biodegradable but also fully recyclable.

One example is polyhydroxyalkanoate (PHA), a family of biodegradable polymers that can be produced from renewable resources such as vegetable oil or sugarcane. PHA is fully biodegradable and can be broken down by microorganisms into water, carbon dioxide, and other harmless substances. Additionally, PHA can be recycled into new products without losing its quality or properties.

Another example is polyethylene furanoate (PEF), a plant-based polymer that can be produced from renewable sources such as sugar cane or corn. PEF has similar properties to conventional PET plastic but is fully biodegradable and can be recycled multiple times without losing its properties.

Other examples of fully recyclable plastics include polyethylene terephthalate glycol (PETG), polylactic acid (PLA), and polybutylene succinate (PBS).

While these new types of plastics offer promising solutions to the plastic waste crisis, they are not yet widely adopted in industry and face challenges such as cost-effectiveness and scalability. However, ongoing research and development in this area are expected to make fully recyclable and biodegradable plastics more feasible for widespread use in the future.

For more green news stories check out our Green Impact section at The Brighter Side of News.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.

Joseph Shavit

Head Science News Writer | Communicating Innovation & Discovery

Based in Los Angeles, Joseph Shavit is an accomplished science journalist, head science news writer and co-founder at The Brighter Side of News, where he translates cutting-edge discoveries into compelling stories for a broad audience. With a strong background spanning science, business, product management, media leadership, and entrepreneurship, Joseph brings a unique perspective to science communication. His expertise allows him to uncover the intersection of technological advancements and market potential, shedding light on how groundbreaking research evolves into transformative products and industries.