Non-electric touchpad is a quantum leap forward in sensor technology

Discover how pneumatic soft touchpads are transforming robotics, healthcare, and extreme environments with precise tactile sensing technology.

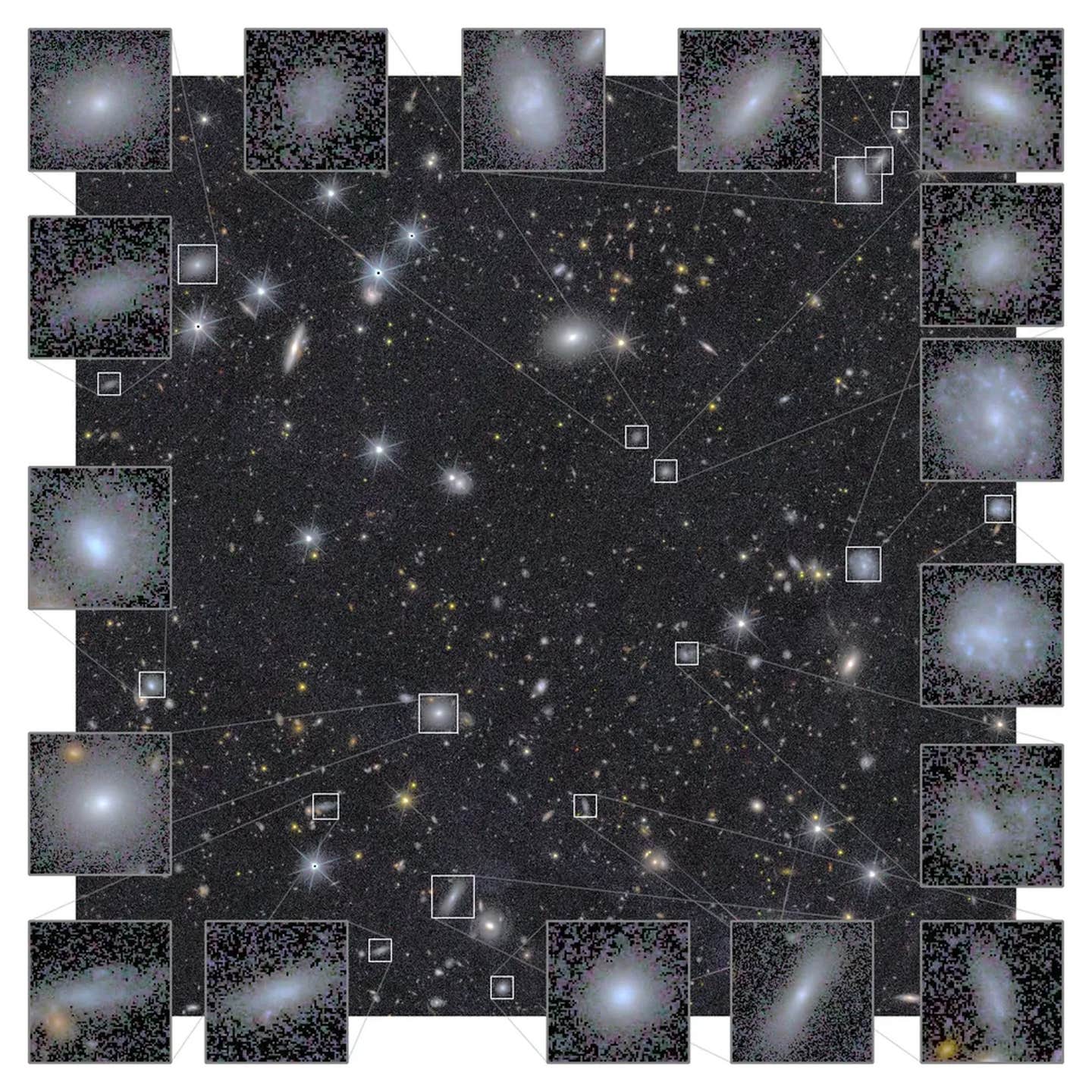

Explore the groundbreaking pneumatic soft touchpad that senses touch without electricity, offering transformative applications in healthcare and robotics. (CREDIT: Shutterstock)

Soft tactile sensors have revolutionized the field of robotics, electronic skins, and wearable devices. While traditional sensors are limited to detecting basic surface compression, advancements now allow for the precise mapping of pressure, contact location, and force distribution. Such innovations pave the way for groundbreaking applications in fields ranging from healthcare to hazardous environment operations.

Traditional tactile sensors often rely on electrical or optical systems, which have limitations in certain applications. Electrical touchpads, for instance, measure touch coordinates using conductive layers. This approach, whether resistive or capacitive, demands rigid materials that are incompatible with soft robotics.

Conductive elastomers, fillers, and liquid alloys offer some flexibility but face issues such as adhesive failures, increased stiffness, and vulnerability to deformation or bubbling.

Optical sensors, while providing pressure distribution data through stretchable waveguides, also struggle with durability due to the dissimilar materials required for functionality. Delamination at material interfaces further complicates their reliability. The mismatch between soft actuators, often fluidic in nature, and electrical or optical sensors necessitates energy transducers, adding complexity and inefficiency.

To address these challenges, researchers have explored fluidic sensors as alternatives. Unlike their electrical counterparts, fluidic sensors operate within the same energy domain as fluidic actuators, creating opportunities for entirely soft, fluidic systems.

These systems are particularly suitable for environments incompatible with electronic devices, such as strong magnetic fields, radiation, or explosive atmospheres. Notably, magnetic resonance imaging (MRI) tools have already incorporated pneumatic devices for tasks like biopsies, demonstrating the compatibility and potential of fluidic technology.

Fluidic sensors detect deformation through two primary methods: changes in air pressure within a deforming chamber or variations in fluidic channel flow resistance. While pressure-based approaches are susceptible to air leakage and long-term instability, flow resistance-based sensors offer greater robustness. This principle mimics electrical strain gauges, measuring pressure drops over channels and resisting leak-induced inaccuracies.

Published in the journal, Advanced Intelligent Systems, researchers at Tampere University have developed the world’s first soft touchpad capable of sensing force, contact area, and location without electricity. This touchpad, constructed entirely of soft silicone, employs 32 pneumatic channels—16 aligned row-wise and 16 column-wise—to detect touch. Each channel, a few hundred micrometers wide, measures changes in flow resistance when compressed, enabling precise tactile mapping.

“Electronic sensors may stop functioning in extreme conditions, such as in a strong magnetic field,” explains Doctoral Researcher Vilma Lampinen. “Since the touchpad is not electric, a strong magnetic field does not affect it, which makes it ideal for use in devices such as MRI machines.”

Related Stories

This breakthrough allows handwritten letters to be reconstructed from touchpad data, showcasing its precision. Additionally, it can detect multiple simultaneous touches and map tactile pressure across its surface. Unlike traditional electrical touchpads, this soft micropneumatic touchpad offers a robust, flexible alternative that adapts seamlessly to various environments.

One significant application of this technology lies in healthcare. The sensor’s non-electric design makes it suitable for integration with MRI-guided robots, such as those used for cancer biopsies.

Pneumatic robots can operate within MRI scanners, leveraging sensor data to guide precise movements without interference from magnetic fields. Such innovations could enhance diagnostic and therapeutic procedures, particularly in oncology.

The technology’s compatibility with extreme environments extends its utility to fields like nuclear decontamination, offshore oil operations, and explosive atmospheres. Its resilience to radiation and sparking hazards ensures safety and reliability in scenarios where electronic devices would fail.

Moreover, the flexibility of silicone as a material enables the integration of these sensors into soft robotics and wearable devices. Soft robotic hands, for instance, could replace traditional prosthetics on production lines. These hands, equipped with touch sensors, could deliver delicate grips while being safer, lighter, and potentially more cost-effective.

“Soft robotic hands could be used to replace current prosthetic hands on, e.g., production lines,” says Lampinen. “Being soft, they are safer, lighter and potentially cheaper to manufacture. Touch sensors around the hand would also enable a more delicate grip.”

Wearable devices, enhanced with these sensors, could also play a pivotal role in rehabilitation. Movement aids made of soft materials would offer improved comfort compared to rigid counterparts. By integrating tactile sensing, such devices could provide real-time feedback, facilitating advanced therapeutic interventions.

The development of the soft micropneumatic touchpad marks a significant step toward replacing electronic tactile sensors with fluidic alternatives. This innovation promises to enhance the functionality and adaptability of soft devices. Future advancements could refine the resolution and scalability of such sensors, further broadening their applications.

For instance, integrating data-driven algorithms with these tactile systems could improve their ability to interpret complex touch patterns. Neural networks have already been used to infer contact forces and locations, hinting at the potential for more sophisticated, AI-driven tactile systems. Additionally, as the demand for environmentally resilient technologies grows, the role of fluidic sensors in sustainable and robust device design is likely to expand.

Soft tactile sensors are not just reshaping robotics and medical devices; they are also redefining what is possible in environments where traditional electronics falter. This transformative technology underscores the power of interdisciplinary innovation, bridging material science, engineering, and computational techniques to address real-world challenges.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Rebecca Shavit

Science & Technology Journalist | Innovation Storyteller

Based in Los Angeles, Rebecca Shavit is a dedicated science and technology journalist who writes for The Brighter Side of News, an online publication committed to highlighting positive and transformative stories from around the world. With a passion for uncovering groundbreaking discoveries and innovations, she brings to light the scientific advancements shaping a better future. Her reporting spans a wide range of topics, from cutting-edge medical breakthroughs and artificial intelligence to green technology and space exploration. With a keen ability to translate complex concepts into engaging and accessible stories, she makes science and innovation relatable to a broad audience.