Lunar-based manufacturing: Building humanity’s future on the Moon

Advancements in lunar manufacturing using 3D printing, robotics, and lunar regolith are paving the way for sustainable Moon exploration.

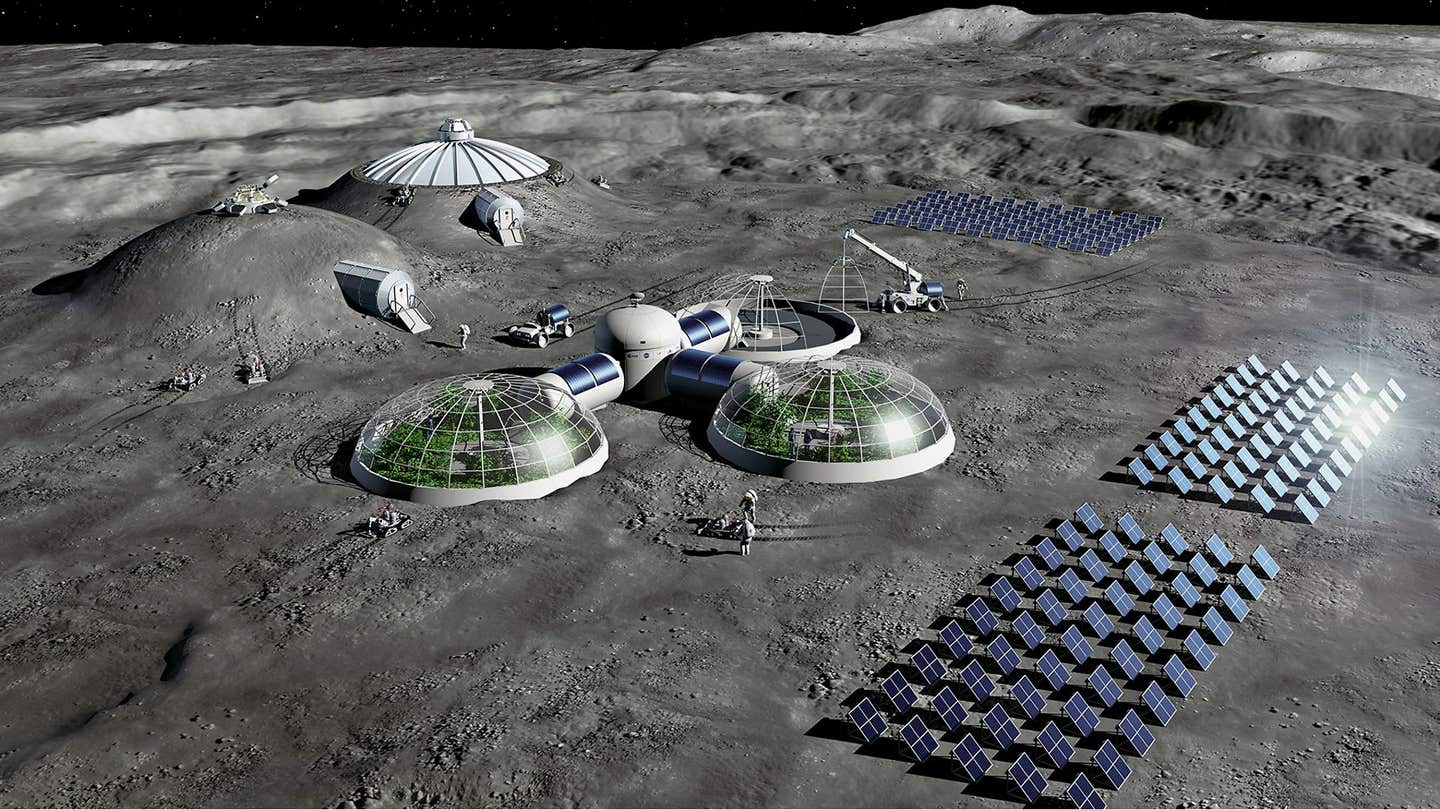

Cutting-edge technologies like 3D printing and robotics are transforming lunar-based manufacturing, paving the way for a sustainable future on the Moon. (CREDIT: CC BY-SA 4.0)

Establishing a permanent presence on the Moon is no longer confined to the realm of science fiction. The Artemis program, alongside international efforts, is bringing humanity closer to this ambitious goal.

However, transforming the Moon’s desolate, radiation-bombarded surface into a habitable outpost requires overcoming formidable challenges. The key lies in lunar-based manufacturing and construction (LBMC), a field that combines cutting-edge technology, innovative materials, and adaptive problem-solving.

The Challenges of Lunar Construction

Building on the Moon presents unique obstacles. The absence of atmosphere, extreme temperatures, and a surface covered in fine, abrasive dust known as lunar regolith make traditional construction methods impractical. Transporting all necessary materials from Earth would be prohibitively expensive and logistically complex.

To reduce dependency on Earth’s resources, researchers are focusing on in-situ resource utilization (ISRU) — the process of using local materials like regolith for construction.

Dr. Mohammad Azami, a PhD candidate at Concordia University’s Aerospace Robotics Lab (CUARL), emphasizes the importance of self-reliance in lunar missions. “A crucial step is to be able to manufacture whatever is needed on-site,” Azami explains. This approach minimizes payload costs and ensures timely repairs and maintenance without waiting for Earth-based resupply missions.

Three technologies are at the forefront of LBMC: additive manufacturing (AM), robotics, and artificial intelligence (AI). Additive manufacturing, commonly known as 3D printing, is particularly promising. Unlike traditional methods, 3D printing can create complex structures layer by layer, using fewer raw materials and allowing for rapid customization.

“For everything that needs to be built, it will probably be the first time,” notes Krzysztof Skonieczny, associate professor at Concordia’s Institute of Aerospace Design and Innovation. “It will have to be done based on inputs from astronauts or Earth-based specialists who can beam up designs.” This adaptability is crucial in the unpredictable environment of the Moon.

Related Stories

Azami’s research has led to a mobile 3D printing robot capable of using a composite of polyether ether ketone (a space-grade polymer) and a lunar dust simulant. This innovation demonstrates the potential of regolith not only as a construction material but also as a radiation shield. The dust’s natural properties make it an effective barrier against harmful solar radiation, reducing the need to transport insulation materials from Earth.

Energy and Sustainability on the Moon

While the promise of using local resources is exciting, significant hurdles remain. Processing lunar regolith into usable materials is energy-intensive. The Moon’s low gravity and vacuum conditions further complicate operations. Solar energy is a potential power source, but ensuring consistent energy supply during the two-week lunar night requires robust storage systems.

Sustainability is a core focus for researchers. Azami and his team aim to maximize resource efficiency, recycling materials wherever possible and minimizing waste. “The longer-term challenge is transitioning toward using local materials primarily, not just as filler, but as the main ingredient,” Azami says. Developing energy-efficient processes for extracting and utilizing lunar resources will be essential for creating a self-sustaining lunar base.

The United States and China have both set ambitious goals to establish a sustained presence on the Moon by the 2030s. Achieving this requires more than just technological advancements. Long-term missions will need to address human biological challenges, such as the effects of low gravity and radiation on the body. Legal and ethical questions about lunar territorial rights also loom large.

Skonieczny points out that manufacturing is only one piece of a larger puzzle. However, advancements in LBMC provide a solid foundation for broader lunar exploration efforts. “These technologies allow us to adaptively and flexibly respond to challenges as they arise,” he says.

Collaborative efforts are driving progress. Researchers from institutions like the University of Toronto and the Canadian Space Agency are contributing valuable insights. The Natural Sciences and Engineering Research Council of Canada (NSERC) has supported key studies, highlighting the importance of international partnerships in advancing lunar exploration.

Looking Ahead

The Moon’s hostile environment may seem insurmountable, but the ingenuity of scientists and engineers is proving otherwise. Through innovative use of resources, cutting-edge technologies, and a commitment to sustainability, humanity is laying the groundwork for a permanent lunar presence.

The journey ahead will be challenging, but it is one that promises to redefine our relationship with space and unlock new frontiers of human potential.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joseph Shavit

Head Science News Writer | Communicating Innovation & Discovery

Based in Los Angeles, Joseph Shavit is an accomplished science journalist, head science news writer and co-founder at The Brighter Side of News, where he translates cutting-edge discoveries into compelling stories for a broad audience. With a strong background spanning science, business, product management, media leadership, and entrepreneurship, Joseph brings a unique perspective to science communication. His expertise allows him to uncover the intersection of technological advancements and market potential, shedding light on how groundbreaking research evolves into transformative products and industries.