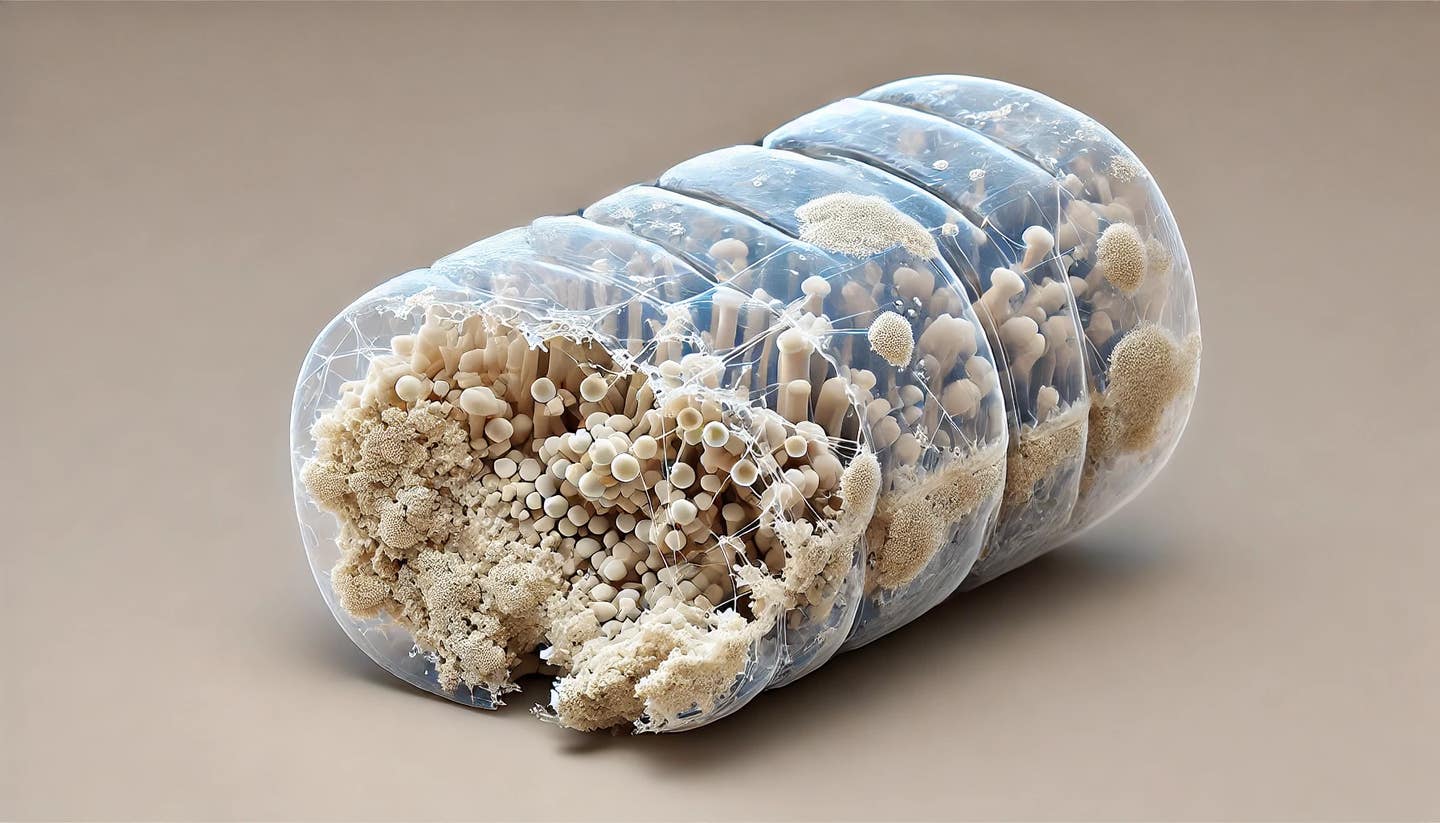

Groundbreaking new plastic completely biodegrades within 30 days

Researchers have developed a biodegradable material that incorporates bacteria, enabling it to decompose naturally at the end of its lifecycle

Unlike conventional plastics, which can take up to 55 days to break down under composting conditions, this cutting-edge material fully decomposes in less than a month. (CREDIT: CC BY-SA 3.0)

Plastic is a major contributor to climate change and environmental harm. While scientists have long been working on ways to reduce plastic use and enhance its recyclability, a new breakthrough has emerged.

A team of researchers has developed a biodegradable material that incorporates bacteria, enabling it to decompose naturally at the end of its lifecycle. Unlike conventional plastics, which can take up to 55 days to break down under composting conditions, this cutting-edge material fully decomposes in less than a month.

The inspiration behind this new technology comes from plastic-eating proteins, first discovered in 2016 in a species of bacteria at a recycling facility in Japan. Since then, researchers have identified several other bacteria species that have naturally evolved enzymes capable of breaking down plastic. These naturally occurring proteins have served as the blueprint for creating even more efficient synthetic versions, designed to target and degrade plastic waste.

At the forefront of this research is a team from the Chinese Academy of Sciences (CAS), led by synthetic biologist Chenwang Tang. Their breakthrough involves embedding bacterial spores that secrete these plastic-degrading enzymes directly into the structure of polycaprolactone (PCL) plastic. As the plastic starts to degrade, these enzymes are released, accelerating the breakdown process.

Enzymes, however, are typically large and complex proteins that can be unstable or fragile. To overcome this challenge, the researchers engineered the gene for a lipase enzyme from the bacterium Burkholderia cepacia (BC) into the DNA of another microbe, Bacillus subtilis. In its spore form, Bacillus subtilis is highly resistant to extreme temperatures and pressures, making it ideal for this application.

Related Stories

When the surface of the plastic begins to erode, the embedded spores start to germinate, and the growing Bacillus subtilis produces the BC-lipase enzyme. This enzyme then works to degrade the PCL molecules almost completely.

The research team further enhanced this process by incorporating a second lipase enzyme from the yeast Candida antarctica. With this addition, the plastic degraded within a week, a significant improvement compared to the three weeks required for traditional PCL plastics treated in the same way.

PCL plastics have the advantage of requiring less extreme temperatures and pressures for production compared to other plastics. To test the resilience of the spores during the manufacturing process of other types of plastics, the researchers engineered the bacteria to express fluorescent markers. These markers were used to determine whether the spores survived the processing conditions.

The team tested several plastic types, including PBS (polybutylene succinate), PBAT (polybutylene adipate-co-terephthalate), PLA (polylactic acid), PHA (polyhydroxyalkanoates), and even PET (polyethylene terephthalate), which requires temperatures as high as 300°C. Remarkably, when these spore-embedded plastics were physically degraded or boiled, they began to glow, indicating that the spores had indeed survived the harsh conditions and released their contents as intended.

In an additional test, the research team at CAS found that the living plastics remained stable even after being soaked in soda (Sprite) for 60 days, highlighting their potential use as packaging materials. Furthermore, the plastics disintegrated thoroughly without the need for antibiotics, showcasing the robustness of the system.

While this study is currently a proof of concept, it offers an intriguing and innovative approach to addressing the growing problem of plastic pollution. In the last two decades, plastic manufacturing has doubled, exacerbating the environmental issues associated with plastic waste. However, this new technology from CAS could pave the way for sustainable, biodegradable materials that don't linger in the environment for centuries after a single use.

The study was published in Nature Chemical Biology, marking a significant step forward in the quest for more eco-friendly plastic alternatives.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.