Groundbreaking chemical process converts plastic waste into electronic devices

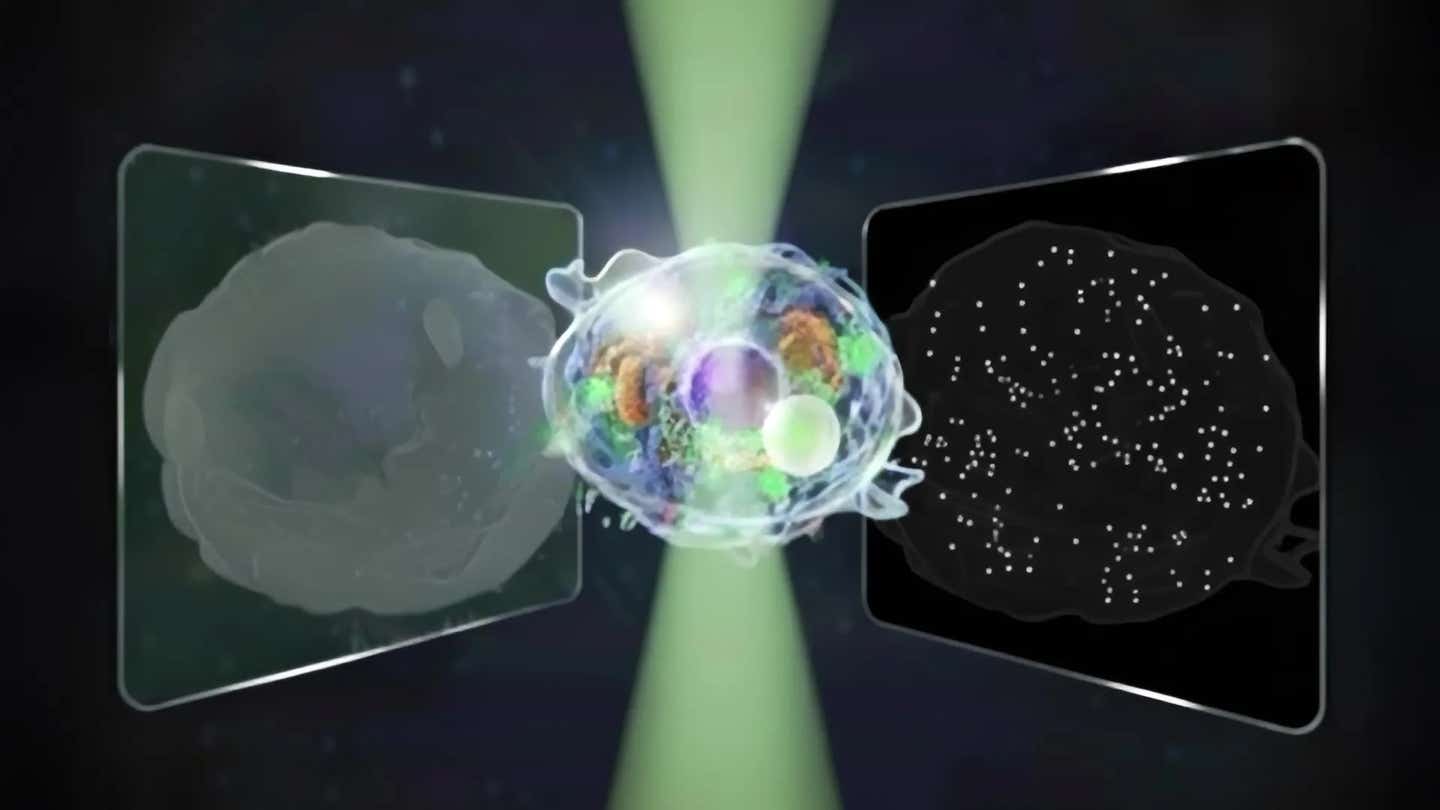

The study demonstrates how upgraded plastic waste can be successfully incorporated into functional electronic devices.

A study demonstrates how upgraded plastic waste can be successfully incorporated into functional electronic devices (CREDIT: PBS)

Imagine being able to transform everyday waste into valuable materials for cutting-edge electronics. That’s precisely what researchers from the University of Delaware and Argonne National Laboratory have achieved. They have developed a groundbreaking chemical reaction that converts Styrofoam into a high-value conducting polymer called PEDOT.

This advancement, detailed in a recent paper published in JACS Au, showcases how upgraded plastic waste can be incorporated into functional electronic devices, such as silicon-based hybrid solar cells and organic electrochemical transistors.

As part of a team led by Laure Kayser, an assistant professor in UD’s Department of Materials Science and Engineering and Department of Chemistry and Biochemistry, the researchers are no strangers to working with PEDOT. This polymer, known for its electronic and ionic conductivity, piqued their interest for its potential to be synthesized from plastic waste. This intriguing possibility became the foundation of their collaborative project with Argonne chemist David Kaphan.

The journey began when the UD team connected with Kaphan at a research event. Together, they hypothesized that PEDOTcould be produced by sulfonating polystyrene, a synthetic plastic commonly found in disposable containers and packing materials. Sulfonation involves replacing a hydrogen atom with a sulfonic acid group, a process used in creating various products, from dyes to ion exchange resins. The challenge was finding a method that was both efficient and gentle on the polymer chain.

“A reagent that is efficient enough to get really high degrees of functionalization but that doesn't mess up your polymer chain,” explained Kayser, was the goal. They turned to a method from a previous study that used 1,3-Disulfonic acid imidazolium chloride ([Dsim]Cl) for sulfonating small molecules. However, sulfonating a polymer is far more complex. Any errors in the polymer chain could drastically alter its properties.

To tackle this complexity, the researchers embarked on extensive experimentation. “We screened different organic solvents, different molar ratios of the sulfonating agent, and evaluated different temperatures and times to see which conditions were the best for achieving high degrees of sulfonation,” said Kelsey Koutsoukos, a doctoral candidate in materials science and the paper’s second author. Their hard work paid off. They discovered optimal reaction conditions that resulted in high polymer sulfonation with minimal defects, all while using a mild sulfonating agent.

Using waste Styrofoam as a starting material, the team found an efficient way to convert plastic waste into PEDOT. This breakthrough not only showcased an innovative approach to recycling but also held significant promise for electronic applications. Once they had produced PEDOT, the next step was to compare its performance with commercially available PEDOT.

Chun-Yuan Lo, a doctoral candidate in chemistry and the paper’s first author, noted, “We looked at two devices — an organic electronic transistor and a solar cell. The performance of both types of conductive polymers was comparable, and shows that our method is a very eco-friendly approach for converting polystyrene waste into high-value electronic materials.”

The research involved several sophisticated analyses. At UD, they used X-ray photoelectron spectroscopy (XPS) for surface analysis, film thickness analysis at the UD Nanofabrication Facility, and solar cell evaluation at the Institute of Energy Conversion. Argonne provided advanced spectroscopy equipment, like carbon NMR, for detailed polymer characterization. Additional support came from UD professors Robert Opila for solar cell analysis and David C. Martin for electronic device performance analyses.

An unexpected but significant discovery was the ability to use stoichiometric ratios during the reaction. “Typically, for sulfonation of polystyrene, you have to use an excess of really harsh reagents. Here, being able to use a stoichiometric ratio means that we can minimize the amount of waste being generated,” Koutsoukos explained.

This finding opens new avenues for the Kayser group. By fine-tuning the degree of sulfonation, they can alter the polymer’s properties. They’re now exploring how this capability can be used in applications like fuel cells or water filtration devices, where the degree of sulfonation is crucial.

“For the electronic devices community, the key takeaway is that you can make electronic materials from trash, and they perform just as well as what you would purchase commercially,” Kayser emphasized. “For the more traditional polymer scientists, the fact that you can very efficiently and precisely control the degree of sulfonation is going to be of interest to a lot of different communities and applications.”

This research not only advances the field of materials science but also contributes to global sustainability efforts. By providing a new way to convert waste products into valuable materials, the study supports ongoing upcycling and recycling initiatives. “Many scientists and researchers are working hard on upcycling and recycling efforts, either by chemical or mechanical means, and our study provides another example of how we can address this challenge,” Lo said.

In essence, this research is a testament to what can be achieved when innovative thinking meets environmental stewardship. By transforming waste into high-value materials, the team at UD and Argonne has paved the way for more sustainable electronic devices and opened new doors for future research in polymer science. As you delve into this fascinating field, consider the potential impact of turning everyday waste into the technologies of tomorrow.

Note: Materials provided above by the The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.