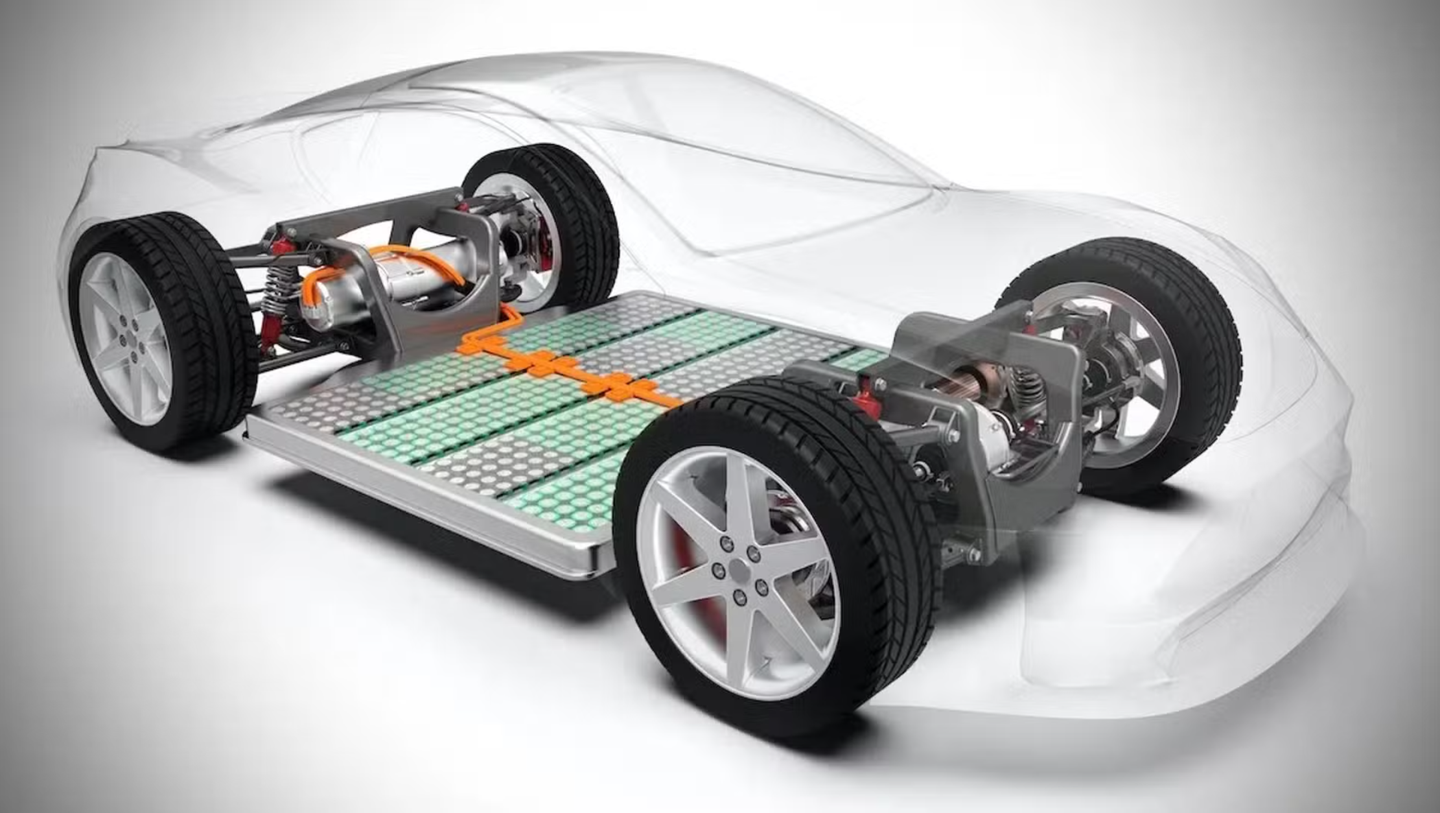

Graphene innovation significantly improves EV battery capacity and safety

This advancement could significantly improve lithium-ion battery safety and performance, addressing challenges in energy storage technology

This not only improves battery safety by efficiently managing heat but also enhances energy density and longevity. (CREDIT: CC BY-SA 4.0)

Researchers from Swansea University, in collaboration with Wuhan University of Technology and Shenzhen University, have developed a breakthrough technique for producing large-scale graphene current collectors. This new advancement could significantly improve lithium-ion battery (LIB) safety and performance, addressing critical challenges in energy storage technology.

The findings, published in Nature Chemical Engineering, outline the first successful approach for creating defect-free graphene foils on a commercial scale, an achievement that could reshape the future of battery technology.

Graphene, a material known for its exceptional properties, now promises extraordinary thermal conductivity in current collectors. The graphene foils developed by this team can conduct heat at up to 1,400.8 W m–1 K–1—almost ten times greater than traditional copper and aluminum current collectors used in lithium-ion batteries.

This enhanced conductivity plays a crucial role in efficiently managing the intense heat generated within high-energy lithium-ion batteries, such as those used in electric vehicles.

Dr. Rui Tan, a co-lead author from Swansea University, highlights the importance of this development, stating, “Our method allows for the production of graphene current collectors at a scale and quality that can be readily integrated into commercial battery manufacturing.

This not only improves battery safety by efficiently managing heat but also enhances energy density and longevity.” By replacing traditional metal collectors, graphene-based collectors offer a safer alternative by preventing the buildup of extreme heat, which can lead to battery failure and even fires or explosions.

One of the most significant challenges in battery technology is preventing thermal runaway—a dangerous condition in which a battery generates excessive heat that it cannot dissipate, leading to potential failure. These new graphene foils are designed to dissipate heat more effectively, reducing the likelihood of thermal runaway.

“Our dense, aligned graphene structure provides a robust barrier against the formation of flammable gases and prevents oxygen from permeating the battery cells, which is crucial for avoiding catastrophic failures,” explained Dr. Jinlong Yang, another co-lead author from Shenzhen University.

Related Stories

Beyond heat management, these graphene foils show remarkable durability. In a key demonstration, the researchers produced a 200-meter-long graphene foil with a thickness of just 17 micrometers.

This foil retained high electrical conductivity even after being bent over 100,000 times, showcasing its flexibility and resilience. Such durability makes the material suitable not only for batteries but also for flexible electronics and other advanced applications.

The scalability of this process marks a significant leap for graphene applications. The technique enables the production of graphene foils in customizable thicknesses, allowing researchers to tailor the foils to meet specific requirements.

For instance, thicker foils could enhance durability in high-stress applications, while thinner foils might be ideal for situations requiring lighter materials. This adaptability opens doors for safer, more efficient energy storage systems across a range of sectors.

Looking forward, the impact of this innovation could be substantial, especially in industries like electric vehicles and renewable energy systems, where efficiency and safety are paramount. These graphene foils could improve battery safety, energy density, and overall performance, making them an attractive option for electric vehicle manufacturers who prioritize safety and longevity.

The research team is continuing to refine this technology with ongoing efforts aimed to reduce the thickness of graphene foils even further while enhancing their mechanical properties.

The team is also exploring additional applications for this material, including redox flow and sodium-ion batteries, with support from Professor Serena Margodonna’s group at Swansea University.

Thermal runaway is one of the most pressing safety issues in lithium-ion batteries. When the internal temperature of a battery exceeds a critical threshold, the battery can begin to produce heat faster than it can dissipate it. This can lead to a cascade of exothermic reactions, resulting in battery failure.

Traditional metal current collectors, such as aluminum and copper, are limited in their ability to transfer heat efficiently, making them inadequate for high-energy-density batteries.

The newly developed graphene current collectors address these limitations. Their high thermal conductivity enables rapid heat transfer, which helps to maintain safe operating temperatures within the battery cells. As a result, the battery's internal structure remains stable, preventing the chemical reactions that lead to thermal runaway.

Graphene’s unique structure not only serves as a robust thermal conductor but also acts as a barrier to oxygen, further enhancing the battery’s safety profile.

In practical applications, lithium-ion batteries with these graphene foils demonstrated faster heat dissipation. This helps prevent local heat concentration within battery packs, a primary contributor to thermal failure.

Batteries equipped with these graphene current collectors were able to maintain stable temperatures, avoiding the fast exothermic reactions that can occur with aluminum and copper foils. This characteristic makes graphene current collectors ideal for high-performance applications, especially in electric vehicles, where safety standards are stringent.

Overall, this innovative approach offers a solution to one of the most significant challenges in battery technology. Graphene foils are not just a laboratory success; they are ready for commercial production on a large scale. By enabling the fabrication of these foils in lengths ranging from meters to kilometers, this technology promises to drive the next generation of energy storage solutions.

The potential of graphene in this role extends beyond lithium-ion batteries. The researchers are exploring applications in other types of batteries, like sodium-ion and redox flow batteries, where high thermal conductivity and flexible design are advantageous.

With this development, the research team has paved the way for safer, more efficient batteries. This is a crucial advancement as the world moves toward renewable energy and electric mobility, both of which demand high-performance, reliable, and safe energy storage solutions.

The innovation not only addresses safety concerns but also offers practical solutions for extending battery lifespan and optimizing energy use in various applications.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer | AI and Robotics Reporter

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a contributor to The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business Administration at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.