Egg whites remove salt and microplastics from seawater with 99% efficiency

The breakthrough came during a faculty meeting, where Arnold was sitting, staring at his sandwich’s bread, and had an idea.

[July 16, 2023: Staff Writer, The Brighter Side of News]

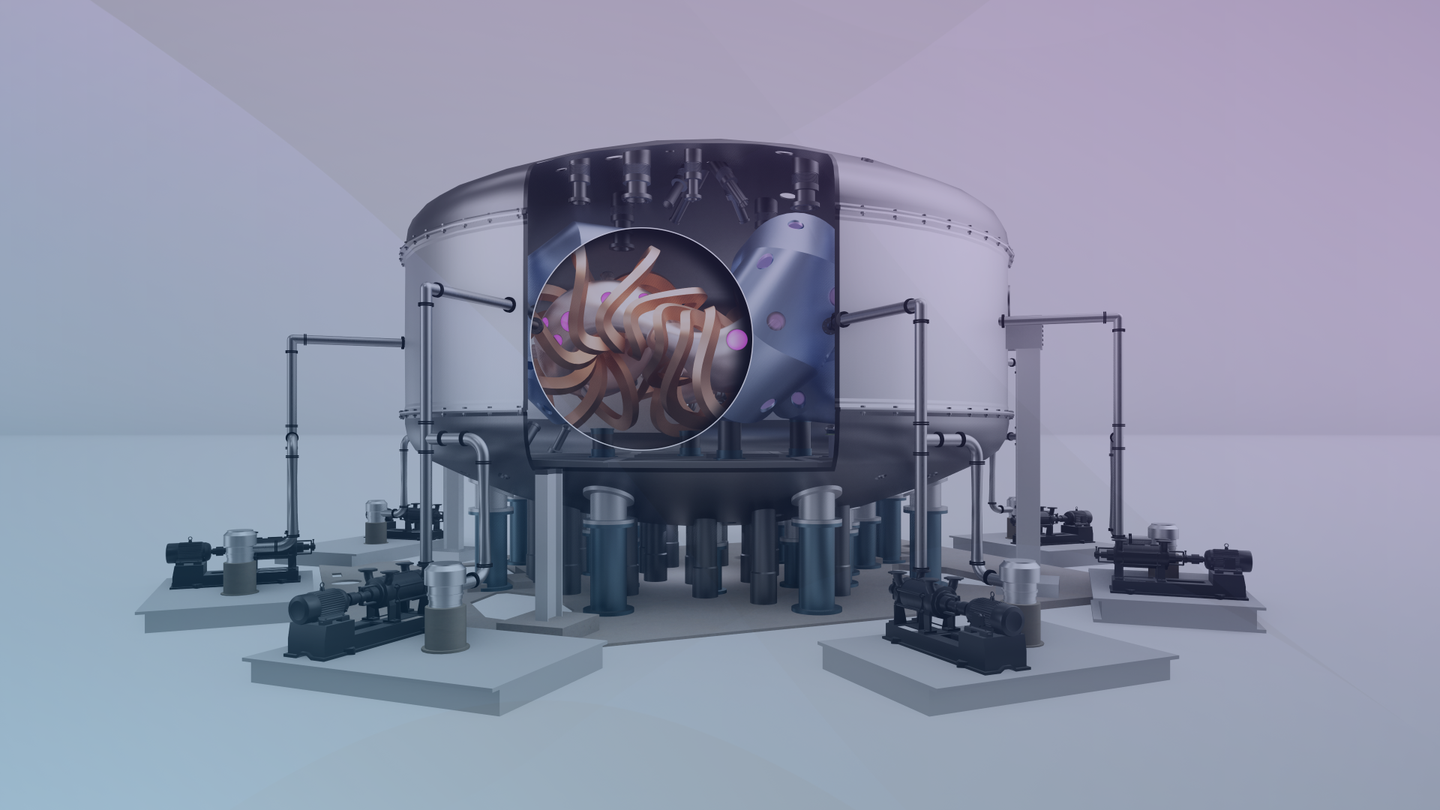

The material is an aerogel, a lightweight and porous material that can be used in many types of applications, including water filtration. (CREDIT: Creative Commons)

Princeton Engineering researchers have made a significant breakthrough in the development of a new material that can cheaply remove salt and microplastics from seawater using egg whites. The material is an aerogel, a lightweight and porous material that can be used in many types of applications, including water filtration, energy storage, and sound and thermal insulation.

Craig Arnold, the Susan Dod Brown Professor of Mechanical and Aerospace Engineering and vice dean of innovation at Princeton, leads the team in creating new materials for engineering applications, including aerogels.

The breakthrough came during a faculty meeting, where Arnold was sitting, staring at his sandwich's bread, and had an idea. He asked his lab group to create different bread recipes mixed with carbon to see if they could recreate the aerogel structure he was looking for. After several failed attempts, the team kept eliminating ingredients until only egg whites remained, creating the structure they needed.

The egg whites are a complex system of almost pure protein, which when freeze-dried and heated to 900 degrees Celsius in an environment without oxygen, create a structure of interconnected strands of carbon fibers and sheets of graphene. In a recent paper published in Materials Today, Arnold and his co-authors showed that the resulting material can remove salt and microplastics from seawater with 98% and 99% efficiency, respectively.

Related Stories

The material's significant benefits include its inexpensiveness to produce, energy efficiency to use, and high effectiveness. Compared with reverse osmosis, which requires significant energy input and excess water for operation, this filtration process requires only gravity to operate and wastes no water. The material's potential applications also include energy storage and insulation.

The researchers caution against competing against the food cycle, but because other proteins also worked, the material can potentially be produced in large quantities relatively cheaply without impacting the food supply. The next step for the researchers is to refine the fabrication process so it can be used in water purification on a larger scale.

The research included contributions from the departments of chemical and biological engineering and geosciences at Princeton and elsewhere. "It's one thing to make something in the lab," said Arnold, "and it's another thing to understand why and how."

Graphical abstract: the G-CF aerogel significantly improves upon existing materials, capturing 98.2% of ionic impurities and 99.9% of nano/microplastic contamination from seawater. (CREDIT: Materials Today)

Collaborators who helped answer the why and how questions included professors Rodney Priestley and A. James Link from chemical and biological engineering, who helped identify the transformation mechanism of the egg white proteins at the molecular level. Princeton colleagues in geosciences assisted with measurements of water filtration.

The breakthrough material's development is a major step in addressing the growing water crisis globally, where over 2.2 billion people lack access to clean drinking water. The UN predicts that by 2025, half the world's population will be living in water-stressed areas.

The structure of the aerogel is formed by graphene sheets stretched across carbon fiber networks. (CREDIT: Shaharyar Wani)

Water scarcity is a pressing issue, and this new material could potentially be a game-changer. However, it is important to note that the material is still in the development stage and needs further refinement before it can be used on a larger scale. The researchers are working to refine the fabrication process so it can be used in water purification and expand the material's potential applications to other areas.

Arnold and his team's breakthrough in creating this new material has opened up many possibilities in developing new materials for engineering applications that can help address the world's most pressing issues, including energy storage, sound and thermal insulation, and water filtration.

For more green news stories check out our Green Impact section at The Brighter Side of News.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get the Brighter Side of News' newsletter.

Joseph Shavit

Head Science News Writer | Communicating Innovation & Discovery

Based in Los Angeles, Joseph Shavit is an accomplished science journalist, head science news writer and co-founder at The Brighter Side of News, where he translates cutting-edge discoveries into compelling stories for a broad audience. With a strong background spanning science, business, product management, media leadership, and entrepreneurship, Joseph brings a unique perspective to science communication. His expertise allows him to uncover the intersection of technological advancements and market potential, shedding light on how groundbreaking research evolves into transformative products and industries.