Breakthrough light-absorbing material significantly increases solar power output

Oxford scientists have developed a flexible, ultra-thin solar material that could replace silicon panels, transforming everyday surfaces into power generators.

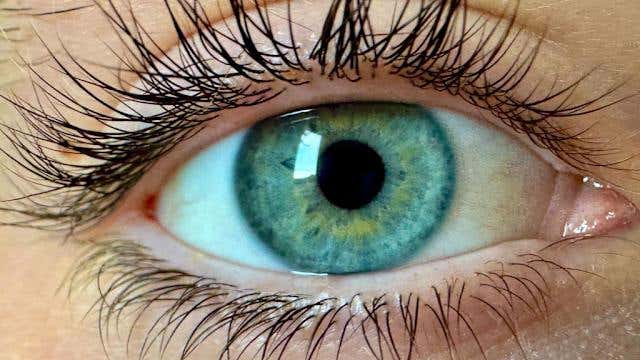

Dr Shuaifeng Hu, Post Doctoral Fellow at Oxford University Physics. (CREDIT: University of Oxford)

Scientists at Oxford University’s Physics Department have developed a groundbreaking technology that could transform how we generate solar electricity, offering a departure from the reliance on traditional silicon-based solar panels. Their innovation introduces a new material that can be coated onto everyday objects like cars, mobile phones, and even buildings, providing a versatile and efficient way to capture solar energy.

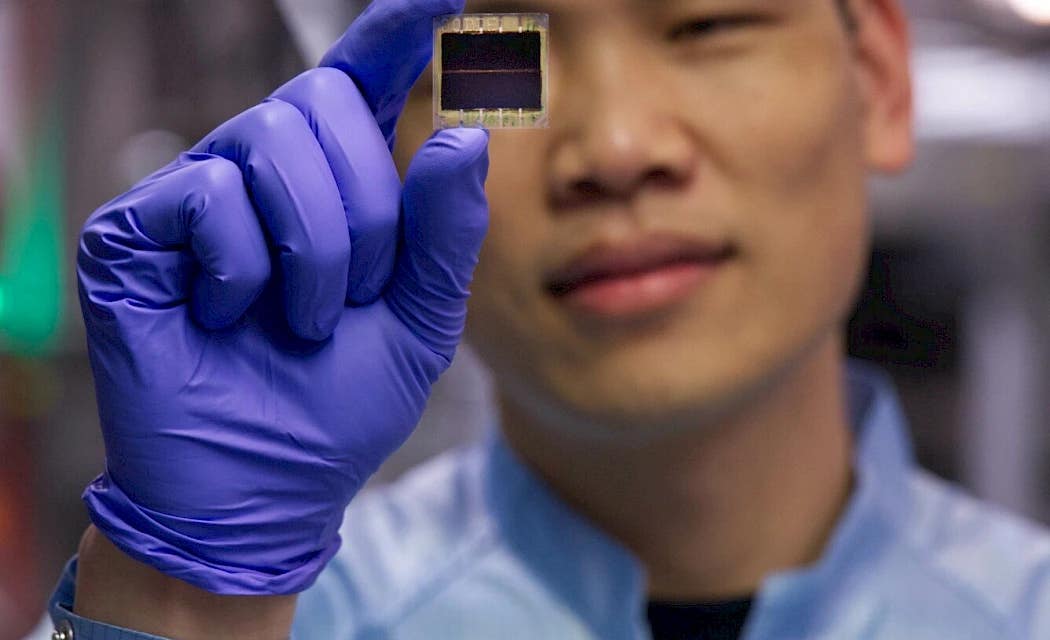

For the first time, a light-absorbing material thin and flexible enough to coat nearly any surface has been developed. This new material uses a multi-junction design, which stacks several layers of light-absorbing cells. This design allows the solar cells to capture a broader spectrum of light, resulting in more electricity from the same amount of sunlight.

Certified by Japan's National Institute of Advanced Industrial Science and Technology (AIST), this ultra-thin material delivers over 27% energy efficiency—marking the first time that a non-silicon solar material has matched traditional silicon photovoltaic technology.

According to Dr. Shuaifeng Hu, a Postdoctoral Fellow at Oxford University, the efficiency increase is a significant breakthrough. “In just five years of using our stacking, or multi-junction, approach, we’ve raised power conversion efficiency from around 6% to over 27%. We believe this method could eventually lead to efficiencies exceeding 45%,” he explained.

The material’s current efficiency of 27% rivals the energy output of existing silicon solar panels, which typically convert around 22% of sunlight into electricity. However, the new material's flexibility gives it a major advantage. It measures just over one micron thick, making it nearly 150 times thinner than silicon wafers. This flexibility opens the door to solar energy applications on an array of surfaces where conventional panels are impractical.

Dr. Junke Wang, another key figure in the research, highlighted the material's unique benefits. “By using new materials that can be applied as a coating, we’ve shown we can replicate and even outperform silicon, while gaining the advantage of flexibility,” she said. “This is crucial because it allows us to generate more solar power without needing silicon-based panels or specially-built solar farms.”

Related Stories

The researchers foresee this advancement not only improving solar efficiency but also reducing the overall cost of solar power. Since 2010, the average global cost of solar electricity has plummeted by nearly 90%, making it about one-third cheaper than electricity generated from fossil fuels. By utilizing innovative materials like thin-film perovskite, the cost of solar energy could drop even further, as the need for expensive silicon panels and large-scale solar farms decreases.

“We can envision perovskite coatings being applied to surfaces such as car roofs, building facades, and even the backs of mobile phones,” Dr. Wang noted. “If we can generate solar energy from these surfaces, we might reduce the long-term need for large solar farms or silicon panels.”

This pioneering approach to solar technology builds on Oxford University’s decade-long research into photovoltaics, led by Professor Henry Snaith, a prominent figure in the field of renewable energy. Professor Snaith’s team of 40 scientists at Oxford has been at the forefront of photovoltaics research, particularly in exploring thin-film perovskite materials.

Their work has already caught the attention of several industries, including utilities, construction, and automotive manufacturing. Companies in these sectors see the potential for widespread commercial application, and the research team's developments have strong commercial viability.

Oxford PV, a UK-based company founded in 2010 by Professor Snaith to commercialize perovskite technology, recently opened the world’s first large-scale manufacturing line for “perovskite-on-silicon” tandem solar cells. Located in Brandenburg-an-der-Havel, Germany, the factory represents a significant leap in making the technology widely available. The tandem solar cells produced there could redefine how solar energy is harvested.

Professor Snaith explained why manufacturing was initiated in Germany rather than the UK. “We initially explored UK sites, but the government has not yet provided the financial or commercial incentives found in other parts of Europe and the United States,” he said. “Up to now, the UK has focused mainly on solar farms, but the real growth will come from bringing innovations to market.”

The research being conducted in Oxford's laboratories has the potential to revolutionize solar energy. By moving away from large-scale solar farms and embracing flexible solar coatings, new industries could emerge around the production of solar energy-generating materials.

Professor Snaith believes the UK has an opportunity to lead in this global industry, but he warns that government support is critical. “Without new incentives and a clear pathway to scale up manufacturing, the UK could miss out on leading this rapidly growing sector in the green economy,” he cautioned.

This innovation doesn’t just promise cleaner, cheaper energy—it offers a more sustainable and flexible solution for generating solar power. As the demand for renewable energy grows, advancements like this could play a vital role in reshaping the global energy landscape, pushing the boundaries of what solar technology can achieve.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer | AI and Robotics Reporter

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a contributor to The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business Administration at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.