A tiny amount of this powder can absorb as much CO2 as a tree

Researchers developed a new material that could transform DAC technology and pull CO2 from the air more effectively than existing methods.

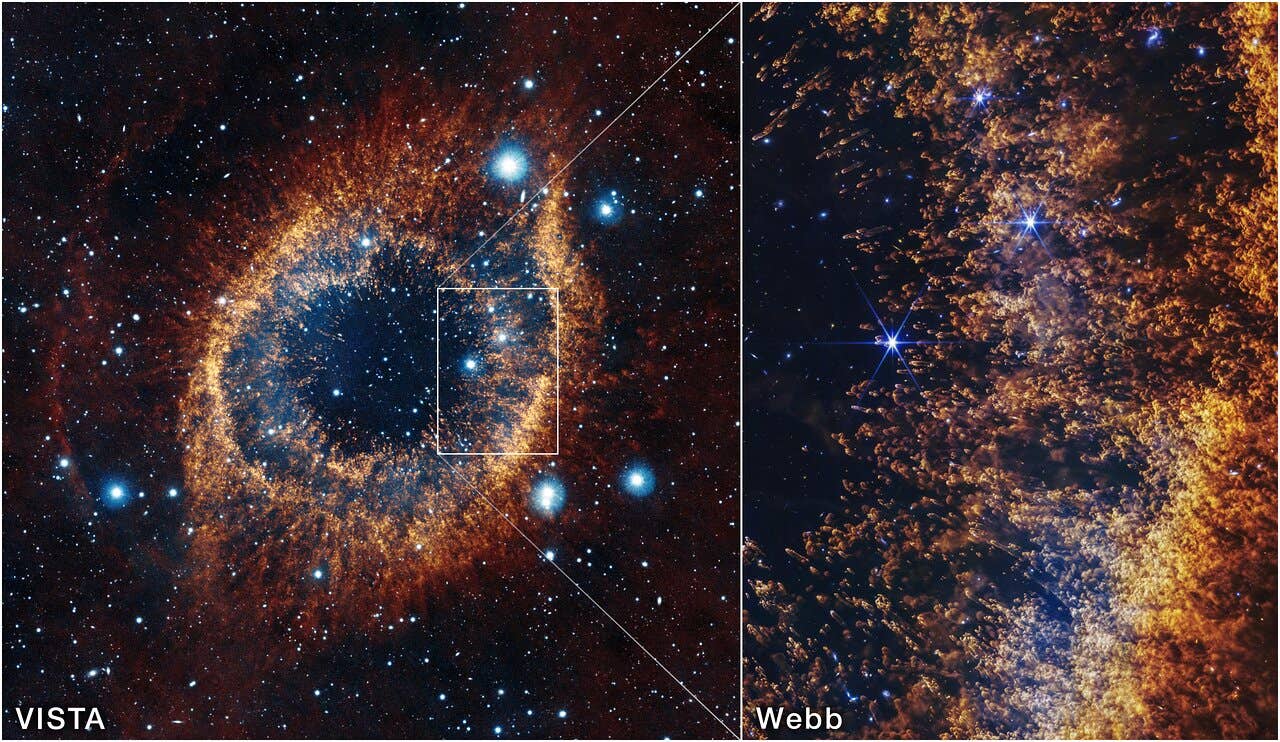

This covalent organic framework (COF) is a porous material capable of capturing CO₂ from ambient air while remaining stable against water and other contaminants. (CREDIT: Zihui Zhou, UC Berkeley)

Efforts to combat climate change have intensified as carbon dioxide levels in the atmosphere continue to rise. Technologies designed to capture and store this greenhouse gas are now seen as critical tools in the fight to reduce global emissions.

While existing carbon capture methods work well for concentrated sources like power plants, removing CO2 from the open air is far more difficult. In the atmosphere, carbon dioxide is highly diluted, making capture less efficient and more energy-intensive.

Despite these challenges, scientists see direct air capture (DAC) as a key strategy for reducing atmospheric carbon dioxide. Current levels have climbed to 426 parts per million—50% higher than before the Industrial Revolution—intensifying the need for scalable solutions.

The Intergovernmental Panel on Climate Change (IPCC) has emphasized the importance of DAC in limiting global temperature rise. Without it, reaching the goal of keeping warming below 1.5°C (2.7°F) may not be possible.

Researchers at the University of California, Berkeley, have developed a new material that could transform DAC technology. This innovation offers a promising approach to pulling CO2 from the air more effectively than existing methods.

The material, a covalent organic framework (COF), captures carbon dioxide while resisting breakdown from moisture or contaminants—two factors that hinder current DAC systems. Omar Yaghi, a UC Berkeley chemistry professor leading the research, sees it as a breakthrough in carbon capture.

"We took a powder of this material, put it in a tube, and passed Berkeley air—just outdoor air—into the material to see how it would perform," Yaghi explained. "It was beautiful. It cleaned the air entirely of CO2. Everything."

The experiment demonstrated that the material not only worked but also surpassed other DAC technologies in efficiency. Unlike many existing materials, it maintained performance under real-world conditions.

According to Yaghi, this new COF could be easily integrated into existing carbon capture systems that are currently being developed or deployed to reduce CO2 emissions from industrial sources and capture atmospheric carbon for underground storage.

Related Stories

In addition to its effectiveness, this material offers a compelling comparison to trees when it comes to capturing carbon. UC Berkeley graduate student Zihui Zhou, the first author of the research paper, highlighted the material’s impressive capacity.

Just 200 grams of the COF—less than half a pound—can capture 20 kilograms (44 pounds) of CO2 per year, equivalent to the carbon absorption of a mature tree. Zhou also emphasized the long-term impact of DAC technology in reversing the rise in atmospheric CO2 levels.

"Flue gas capture is a way to slow down climate change because you are trying not to release CO2 to the air," Zhou said. "Direct air capture is a method to take us back to like it was 100 or more years ago."

Today, atmospheric CO2 levels have exceeded 420 ppm, but experts project that this could rise to 500 or 550 ppm before effective flue gas capture is fully deployed. If the world hopes to reduce CO2 levels back to 400 or even 300 ppm, DAC systems will need to play a significant role.

The COF developed by Yaghi and his team builds on decades of research into porous materials for carbon capture. Yaghi, the inventor of both COFs and metal-organic frameworks (MOFs), has been working on such technologies since the 1990s, long before DAC became a widely recognized approach to climate mitigation.

MOFs, which consist of metal atoms and organic molecules arranged in a crystalline structure, have proven effective for capturing gases, including carbon dioxide, but they have certain limitations.

One of Yaghi’s previous creations, MOF-808, showed great promise for capturing CO2. However, after hundreds of cycles of use, the MOFs began to degrade. The material’s instability under certain conditions, particularly when exposed to bases like amines (a group commonly used in carbon capture systems), limited its durability.

To address these issues, Yaghi and his colleagues set out to design a more stable material. Their new COF, called COF-999, is held together by strong covalent carbon-carbon and carbon-nitrogen bonds.

Like MOFs, the COF’s pores are lined with amines, which increase the material’s capacity to bind CO2. The result is a material that is highly selective for CO2, water-stable, and capable of being reused for hundreds of cycles without degrading.

“Trapping CO2 from air is a very challenging problem,” Yaghi noted. “You need a material that has high carbon dioxide capacity, that’s highly selective, that’s water stable, oxidatively stable, recyclable, and scalable. It’s a tall order for a material.” Yaghi explained that most current systems rely on energy-intensive processes, such as bubbling exhaust gases through liquid amines, which require substantial energy to regenerate.

The COF-999 material meets many of the stringent requirements for DAC technology. When 400 ppm CO2 air is passed through the COF at room temperature and 50% humidity, it reaches half capacity in 18 minutes and fully fills within two hours. It releases CO2 when heated to just 60°C (140°F), making it much more energy-efficient than other systems. In terms of capacity, COF-999 can hold up to 2 millimoles of CO2 per gram, outperforming many other solid sorbents used for air capture.

One of the most remarkable aspects of COF-999 is its ability to withstand 100 adsorption-desorption cycles without any loss of capacity, a feat unmatched by other materials. Yaghi and his team believe that with further optimization, the material could be even more efficient. “It’s basically the best material out there for direct air capture,” Yaghi said.

Looking ahead, Yaghi is hopeful that artificial intelligence (AI) could help accelerate the development of even more advanced COFs and MOFs. By using AI to predict the optimal chemical conditions for creating new materials, researchers may be able to discover new solutions more quickly.

Yaghi, who serves as the scientific director of UC Berkeley’s Bakar Institute of Digital Materials for the Planet (BIDMaP), is already working on AI-driven approaches to design more cost-effective and scalable carbon capture materials.

"We’re very, very excited about blending AI with the chemistry that we’ve been doing," Yaghi said.

With innovations like COF-999, the future of carbon capture looks promising. These materials could play a pivotal role in reducing atmospheric CO2 levels and helping humanity reach its climate goals.

As researchers continue to push the boundaries of what’s possible, the hope is that these advancements will lead to scalable, deployable solutions that can significantly mitigate the impacts of climate change.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.