Scientists use sunlight to transform greenhouse gases into valuable chemicals

McGill University researchers have created a sunlight-driven process that converts harmful greenhouse gases into valuable products, offering a path towards a sustainable future.

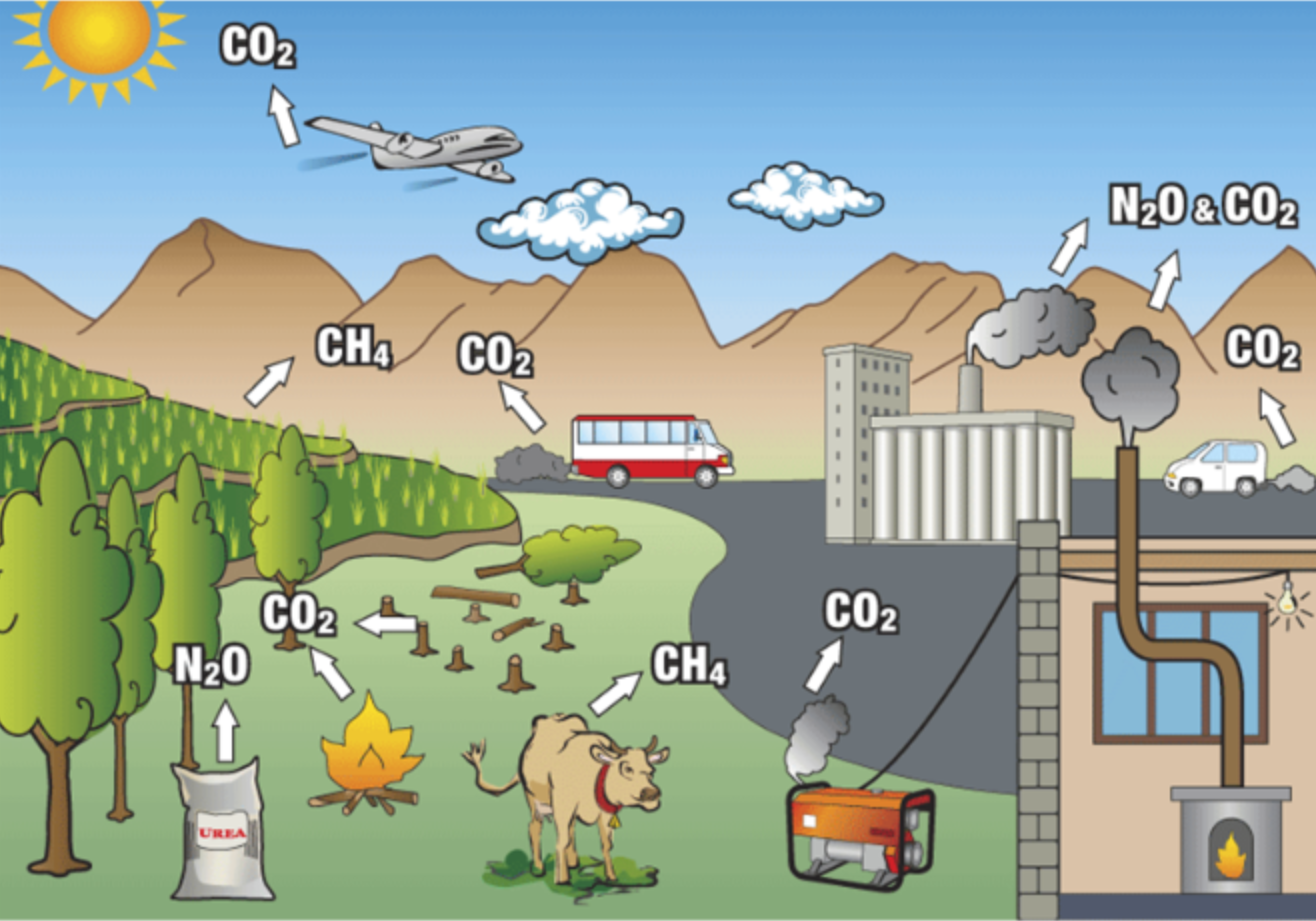

Researchers have developed a breakthrough method to transform two of the most damaging greenhouse gases—methane and carbon dioxide—into valuable chemicals. (CREDIT: Climate Emergency Institute)

Researchers at McGill University have developed a breakthrough method to transform two of the most damaging greenhouse gases—methane and carbon dioxide—into valuable chemicals. This discovery not only holds the potential to help mitigate climate change but also provides a more sustainable means of producing essential industrial products.

The new process relies on sunlight to convert methane and carbon dioxide into green methanol and carbon monoxide in a single reaction. Both of these products play important roles in the chemical and energy industries, marking this advancement as a significant step toward more eco-friendly industrial practices.

“Imagine a world where the exhaust from your car or emissions from a factory could be transformed, with the help of sunlight, into clean fuel for vehicles, the building blocks for everyday plastics, and energy stored in batteries,” explained Hui Su, a Postdoctoral Fellow in McGill’s Department of Chemistry and co-first author of the study. This vision aligns with the promise of the new chemical process, which turns harmful emissions into useful resources.

Inspired by Nature’s Efficiency

The chemical process, detailed in the journal Nature Communications, takes inspiration from nature, specifically from photosynthesis—the way plants use sunlight to convert carbon dioxide and water into glucose and oxygen. This natural process served as the foundation for the researchers' design of a new mechanism that recycles harmful greenhouse gases.

Related Stories

The core of this process lies in the use of a catalyst made from a unique combination of gold, palladium, and gallium nitride. When this catalyst is exposed to sunlight, it initiates a reaction that combines an oxygen atom from carbon dioxide with a methane molecule, resulting in the creation of green methanol. Carbon monoxide is produced as a byproduct, which can also be harnessed for industrial applications.

One of the key advantages of this method is its efficiency. Traditional methods of converting methane and carbon dioxide often require high temperatures and harsh chemicals, both of which are energy-intensive and environmentally unfriendly. However, the process developed by McGill's researchers operates at room temperature, making it a much greener alternative.

"By tapping into the abundant energy of the sun, we can essentially recycle two greenhouse gases into useful products," said Chao-Jun Li, the lead author of the study, a Distinguished James McGill Professor, and Canada Research Chair in Green/Organic Chemistry. Li further emphasized that this light-driven chemical process requires no external heating or harmful chemicals, setting it apart from other methods.

Towards Net-Zero Emissions

This innovative approach aligns with Canada's broader environmental goals. Canada has set a target to achieve net-zero emissions by 2050, and this discovery offers a potentially crucial tool in reaching that goal. “This innovation offers a promising path towards Canada’s target of net-zero emissions by 2050 and turns an environmental challenge into an opportunity for a more sustainable future,” added Jing-Tan Han, a PhD student in McGill’s Department of Chemistry and co-first author of the study.

Methane, a gas that is over 25 times more potent than carbon dioxide in trapping heat in the atmosphere, has long been a major contributor to global warming. Meanwhile, carbon dioxide itself continues to be one of the most abundant and persistent greenhouse gases. Finding ways to repurpose both of these gases into usable materials is a critical step in combating the ongoing climate crisis.

The conversion of methane and carbon dioxide into green methanol is particularly noteworthy. Green methanol is gaining attention as a cleaner alternative to traditional fuels. It can be used in energy storage, as a fuel for vehicles, and as a feedstock in the production of various chemicals, including those used in everyday plastics. Additionally, the carbon monoxide produced in the process can be used in several industrial applications, making this discovery both versatile and impactful.

Backed by Major Research Support

The study and its findings were supported by several prominent research organizations, reflecting the broad interest in developing sustainable chemical processes. Funding for the study came from the Natural Sciences and Engineering Research Council of Canada (NSERC), the Canada Research Chair program, Fonds de Recherche du Québec Nature et technologies (FRQNT), and the Canada Foundation for Innovations (CFI), among others.

McGill University’s own initiatives, such as the McGill Sustainability Systems Initiative (MSSI) fund, also played a role in supporting this research, highlighting the university’s commitment to addressing climate change through innovative science. Furthermore, Axelys and Catalum Technologies contributed to advancing the technology, underscoring the importance of collaborations between academic institutions and the private sector in driving forward breakthroughs in sustainability.

A Bright Path Forward

The potential applications of this research stretch beyond environmental benefits. The ability to use sunlight to transform greenhouse gases into commercially valuable products opens up new opportunities for industries to reduce their carbon footprint while maintaining productivity. The process not only addresses the challenge of rising emissions but also provides a feasible path forward for industries to integrate more sustainable practices into their operations.

This work from McGill University researchers represents a promising development in the field of green chemistry, combining environmental responsibility with industrial innovation. By utilizing renewable energy sources and addressing major environmental challenges, this chemical process may play a key role in the future of sustainable industrial production.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Joshua Shavit

Science & Technology Writer | AI and Robotics Reporter

Joshua Shavit is a Los Angeles-based science and technology writer with a passion for exploring the breakthroughs shaping the future. As a contributor to The Brighter Side of News, he focuses on positive and transformative advancements in AI, technology, physics, engineering, robotics and space science. Joshua is currently working towards a Bachelor of Science in Business Administration at the University of California, Berkeley. He combines his academic background with a talent for storytelling, making complex scientific discoveries engaging and accessible. His work highlights the innovators behind the ideas, bringing readers closer to the people driving progress.