Revolutionary new batteries could help electric cars travel a million kilometers

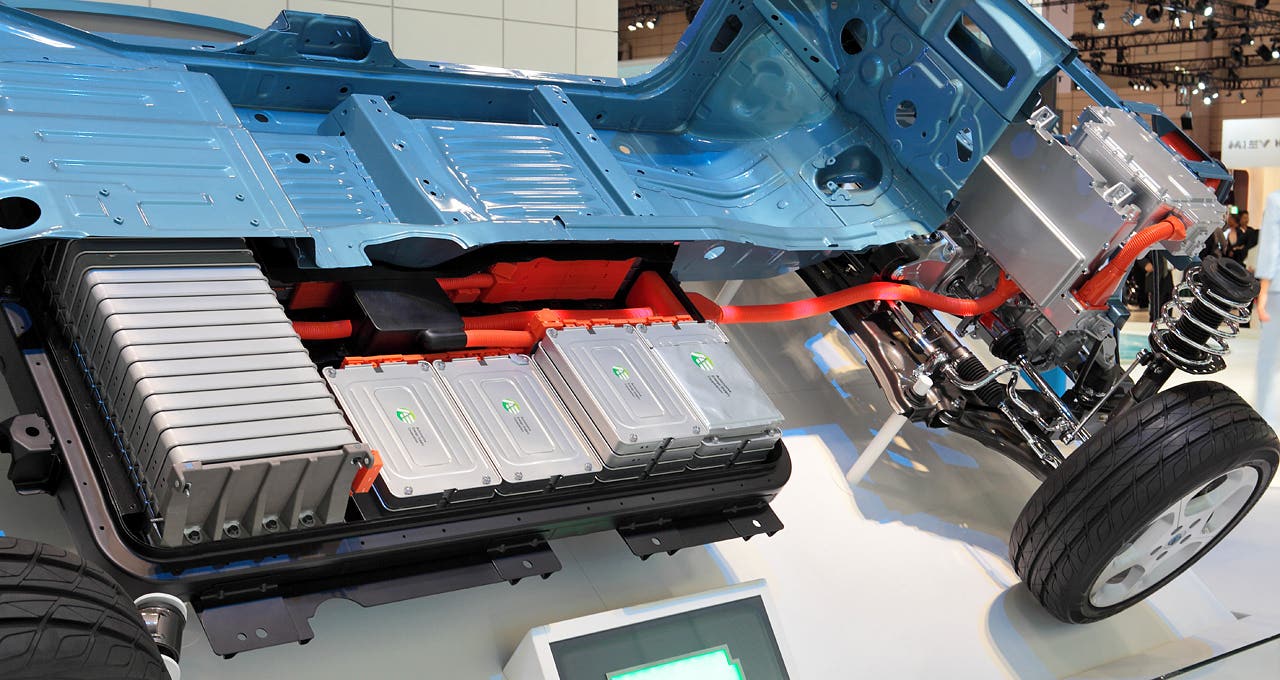

Electric vehicles (EVs) are transforming the transportation landscape, but one major challenge remains: battery lifespan.

Lithium (Li) secondary batteries, commonly used in electric vehicles, store energy by converting electrical energy to chemical energy. (CREDIT: CC BY-SA 3.0)

Electric vehicles (EVs) are transforming the transportation landscape, but one major challenge remains: battery lifespan. Over time, EV batteries degrade, necessitating costly and environmentally damaging replacements.

However, recent research suggests a breakthrough that could significantly extend the lifespan of these batteries, allowing vehicles to drive up to a million kilometers without needing a new battery.

The crux of the issue lies in how lithium-ion batteries, which power most EVs, store and discharge energy. These batteries operate by converting electrical energy into chemical energy for storage and then back into electrical energy when needed.

This process relies heavily on nickel-based cathode materials, known for their ability to store a large quantity of lithium ions essential for the battery's function. Unfortunately, these nickel materials consist of tiny crystals that degrade over time with each charge and discharge cycle, leading to reduced battery performance.

To address this degradation, researchers have explored the potential of producing cathode materials as a single large particle or crystal. Unlike their smaller, crystalline counterparts, these larger particles are less prone to breaking down, potentially offering a more durable solution for EV batteries.

The recent study focused on finding the optimal temperature to synthesize these single-crystal materials with high quality. Researchers experimented with various temperatures, analyzing how each affected the material's capacity and long-term performance. They discovered a critical temperature at which these materials could be produced efficiently and with superior quality, significantly enhancing their durability.

Related Stories:

When the synthesis process occurs above this critical temperature, a phenomenon known as "densification" takes place. During densification, the grains within the material grow larger, and any empty spaces between them are filled. This results in an extremely hard material that resists degradation, promising a much longer battery life.

"We have introduced a new synthesis strategy to enhance the durability of nickel-based cathode materials," explained Kyu-Young Park, a professor at Pohang University of Science & Technology, where the research was conducted. "We will continue our research to make secondary batteries for electric vehicles cheaper, faster, and longer-lasting."

This study, detailed in the journal ACS Applied Materials & Interfaces, marks a significant step toward improving the efficiency and longevity of EV batteries. The findings suggest that with the right production methods, it’s possible to create batteries that not only last longer but also offer greater reliability, potentially driving down the cost of EV ownership and reducing the environmental impact associated with battery replacement.

The research received support from POSCO Holdings and the Basic Research Program of the Ministry of Science and ICT. These findings could play a crucial role in the future of electric vehicles, offering a solution to one of the most significant barriers to widespread EV adoption: battery lifespan.

With ongoing research and development, this breakthrough could lead to the production of EV batteries that are more cost-effective, environmentally friendly, and capable of meeting the demands of long-distance driving without frequent replacements.

This advancement not only holds promise for EV owners but also for the broader goal of reducing carbon emissions and mitigating climate change. The potential for batteries that can last for a million kilometers could be a game-changer in the quest for sustainable transportation solutions.

EV battery disposal - the last mile and beyond

The disposal of electric vehicle (EV) car batteries poses significant environmental challenges. These batteries, typically made from lithium-ion materials, contain toxic metals like cobalt, nickel, and manganese, which can leak into the environment if improperly disposed of. Additionally, the extraction and refining of raw materials for new batteries are resource-intensive and environmentally damaging. Here are the main issues and how scientists are addressing them:

Key Issues:

- Toxic Waste: When EV batteries end up in landfills, the heavy metals and toxic chemicals they contain can contaminate soil and water sources, potentially harming ecosystems and human health.

- Resource Scarcity: Lithium, cobalt, and other materials used in batteries are finite and expensive to mine. Depleting these resources contributes to environmental degradation and makes it harder to sustain the growth of EV technology.

- Recycling Challenges: Recycling lithium-ion batteries is complex and costly. Current methods often require intense energy inputs and specialized facilities, limiting the scalability of these processes.

- Waste Volume: With the growing adoption of EVs, the number of batteries reaching the end of their life cycle is rapidly increasing, creating a potential future waste crisis.

How Scientists Are Tackling the Problem:

- Improved Recycling Techniques: Scientists are developing more efficient ways to recover valuable metals from used batteries. A promising method is hydrometallurgy, where chemicals are used to dissolve metals, allowing them to be separated and reused in new batteries. Another emerging process is direct recycling, where components like the cathode are harvested and reconditioned without breaking them down into their basic elements, preserving more of their original properties.

- Second-Life Applications: EV batteries often still have 70-80% of their storage capacity when they are no longer useful for vehicles. Researchers are exploring how these batteries can be repurposed for other applications, such as stationary energy storage systems for renewable energy grids.

- Designing More Sustainable Batteries: Scientists are also working on creating batteries with fewer critical materials or using recyclable components. Solid-state batteries and sodium-ion batteries are potential alternatives that could be easier to recycle and less harmful to the environment.

- Policy and Infrastructure Development: Governments and researchers are collaborating to develop policies and infrastructure that encourage battery recycling. These efforts include establishing take-back programs, creating incentives for recycling, and improving the logistics for collecting and processing used batteries.

Through these innovations, scientists aim to reduce the environmental impact of EV batteries and create a more sustainable lifecycle for electric vehicles.

Note: Materials provided above by The Brighter Side of News. Content may be edited for style and length.

Like these kind of feel good stories? Get The Brighter Side of News' newsletter.

Rebecca Shavit

Science & Technology Journalist | Innovation Storyteller

Based in Los Angeles, Rebecca Shavit is a dedicated science and technology journalist who writes for The Brighter Side of News, an online publication committed to highlighting positive and transformative stories from around the world. With a passion for uncovering groundbreaking discoveries and innovations, she brings to light the scientific advancements shaping a better future. Her reporting spans a wide range of topics, from cutting-edge medical breakthroughs and artificial intelligence to green technology and space exploration. With a keen ability to translate complex concepts into engaging and accessible stories, she makes science and innovation relatable to a broad audience.